Tahini Making Machine

At Furui Machinery, we specialize in designing and manufacturing industrial-grade tahini making machines. Our tahini making machine delivers smooth consistency, rich flavor, and reliable output from 10 to 3000 kg/h. It ensures top-quality tahini every batch, whether you’re producing artisan paste or running a large-scale line.

- Adjustable stator/rotor system, allowing for precise control of the fineness of the grind.

- Food-grade stainless steel, which is resistant to corrosion and easy to clean.

- Choose a loop return system for fine paste or a wide-mouth discharge for thick, viscous tahini.

Tahini Making Machine

As a manufacturer with deep roots in colloid grinding technology, Furui Machinery offers a comprehensive range of tahini paste machines for sale, with processing capacities from 10 to 3,000 kg/h. We supply not only standalone tahini grinders, but also complete production lines tailored to your scale and process needs. Each machine is equipped with a precision rotor-stator grinding system, specifically designed to deliver consistent, high-quality tahini batch after batch. Whether you're running a family workshop or a commercial-grade factory, our machines ensure superior texture, stable performance, and easy operation.

| Model | Capacity (kg/h) | Fineness (mesh) | Power (kW) | Hopper | Weight (kg) | Dimensions (mm) |

| JMS-50 | 10-20 | 50-100 | 1.5 | 3L | 50 | 530*260*580 |

| JMS-80 | 60-80 | 80-150 | 4 | 8L | 150 | 600*410*930 |

| JMS-110 | 100-200 | 80-150 | 7.5 | 8L | 175 | 700*430*1000 |

| JMS-130 | 300-500 | 80-200 | 11 | 14L | 285 | 990*440*1000 |

| JMS-160 | 500-600 | 80-200 | 15 | 14L | 300 | 1000*460*1050 |

| JMS-180 | 700-800 | 80-200 | 18.5 | 14L | 375 | 1000*490*1100 |

| JMS-210 | 1000-1200 | 80-200 | 30 | 24L | 700 | 1260*600*1230 |

| JMS-240 | 1200-1500 | 80-200 | 45 | 24L | 920 | 1330*630*1280 |

| JMS-300 | 3000-4000 | 80-200 | 75 | 32L | 1300 | 1440*680*1420 |

Role of Colloid Grinder in Tahini Production

The colloid grinder is the core component of a tahini processing line. Its job is not simply to crush sesame seeds, but to emulsify oil and solids into a stable, fine, homogenous paste. It offers:

- A uniform, smooth and creamy texture with no grittiness (fineness up to 150–200 mesh)

- Avoid excessive oil release during grinding

- Enhanced flavor release and smooth mouthfeel

- Adjusted stator gaps to meet various product specifications

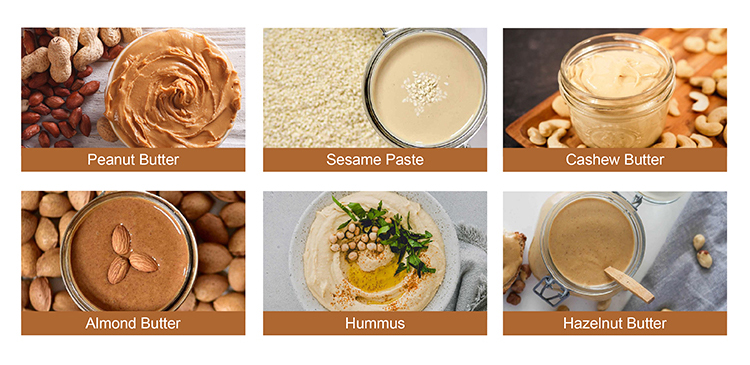

Applications Beyond Sesame Paste

Nut Butter: Peanut butter, almond paste, cashew paste, cocoa paste, and more.

Condiments: Chili sauce, seafood sauce, garlic paste, ginger paste, mayonnaise, ketchup, bone or meat paste, etc.

Food Processing: Cheese slurry, yogurt, cream emulsions, fruit jam, red bean paste, soymilk, peanut milk, and more.

Chemical Industry: Paints and pigments, lubricants and greases, detergents and surfactants, adhesives and sealants.

Cosmetic Industry: Creams and lotions, shampoos and conditioners, and toothpaste production.

Features of Tahini Machine

Custom-engineered Rotor-Stator System

The stator and rotor of tahini grinder are configured with a shearing tooth profile and a diamond-shaped tooth. The former applies powerful mechanical force to grind whole sesame seeds in the initial grinding stage. The latter then generates intense shearing and micro-turbulence, ensuring ultra-fine particle size, smooth texture.

Controlled Grinding Temperature

Our water-cooling system maintains consistent temperatures during extended operation without overheating, preserving sesame’s natural aroma and preventing oil over-release. This ensures a longer shelf life and better product consistency.

Customizable Configuration

Choose between a loop return system for fine recirculation or a wide-mouth discharge for thick, viscous tahini. The machine adapts to your recipe, texture, and processing goals. Available in multiple models, from small workshop units to large-scale production lines.

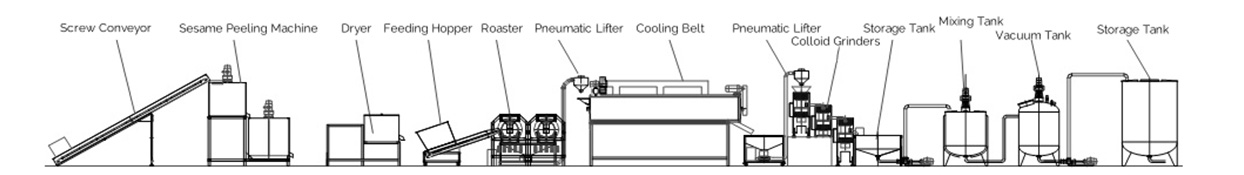

Tahini Production Line

Below is a 200-kg/h tahini production line we offered. The tahini production process and the equipment used include: Sesame peeling (sesame seed peeling and washing machine) - Washing - Drying - Roasting (nut roaster) - Grinding (colloid grinder)- Mixing (Seasoning) - Degassing - Storage.

200kg Tahini Production Line

| No. | Equipment Name | Power (KW) | Size (mm or L) | Qty | Function / Role |

|---|---|---|---|---|---|

| 1 | Screw Conveyor | 0.75 | 4000×600×2500 | 1 | Transfer sesame seeds to the dehulling and washing machine automatically. |

| 2 | Dehulling & Washing Machine | 3.7 | 1730×800×2700 | 1 | Remove sesame husks and clean the seeds thoroughly. |

| 3 | Spin Dryer | – | – | 1 | Remove surface moisture from sesame seeds after washing. |

| 4 | Pneumatic Lifter | 0.55 | 2300×1000×1300 | 1 | Lift the dried sesame seeds into the roasting machine. |

| 5 | Sesame Seed Roaster | 31.1×2 | 2900×1000×1550 | 2 | Roast sesame seeds evenly with electromagnetic heating for better flavor. |

| 6 | Pneumatic Lifter | 3.0 | 2600×600×2500 | 1 | Transfer roasted sesame seeds to the cooling system using air flow. |

| 7 | Cooling Machine | 3.75 | 4000×800×2600 | 1 | Cool the roasted seeds to prevent over-roasting and prepare for grinding. |

| 8 | Pneumatic Lifter | 1.5 | 1700×1100×2500 | 1 | Deliver cooled sesame to the grinding section via air conveying. |

| 9 | Colloid Mill | 11×3 | 1500×1000×2000 | 1 | Grind roasted sesame into smooth, uniform tahini paste in three stages. |

| 10 | Paste Storage Tank | – | 300 L | 1 | Temporarily store the ground tahini before further processing. |

| 11 | Paste Pump | 1.5 | 1200×300×350 | 1 | Transfer tahini paste between tanks and equipment. |

| 12 | Mixing Tank | 2.2 | 300 L | 1 | Mix the tahini for consistency or to add ingredients like salt or oil. |

| 13 | Vacuum Tank | 3.7 | 300 L | 1 | Degas the tahini under vacuum to remove air bubbles and extend shelf life. |

| 14 | Paste Pump | 1.5 | 1200×300×350 | 1 | Pump tahini to the storage tank or packaging line. |

| 15 | Storage Tank | – | 3000 L | 1 | Hold the finished tahini paste in bulk before packaging. |

| 16 | Electric Control Cabinets | – | – | 2 | Centralized control of all equipment, ensuring coordinated and safe operation. |

Sesame Seed Cleaning Machine

Nut Roaster

Colloid Machines for Sale

Solving Your Real Problems

| Pain Point | Our Solution |

|---|---|

| Output is too coarse, inconsistent batches | Precision-adjustable stator/rotor + circulation mode for repeatability |

| Overheating, loss of flavor | Water-cooled design and low-speed options to protect aroma |

| Difficult to clean, labor-intensive | Quick-release head + ergonomic access to all contact surfaces |

| Not sure how to configure your line | We provide a complete production line, from cleaning, roasting, grinding, blending, to filling |

| No tech support after purchase | Dedicated technician assistance, video guidance, and spare part kits |

Sesame Grinding Machine Videos

How to Select the Right Tahini Machine?

- Know your expected hourly processing capacity. This determines not only the right machine model, but also the appropriate motor power and feeding configuration. Avoid overcapacity. Let us recommend the right model for your needs.

- Clarify your texture goal - Smooth or grainy? This defines rotor/stator selection. For small-scale producers aiming for ultra-fine texture, we recommend multiple grinding passes (two or even three times with the same grinder) as a cost-effective solution.

- Sesame paste is heat-sensitive -excessive grinding heat can degrade flavor, aroma, and color. Choose a model with a water-cooling system if you're processing continuously or at high capacity.

- Choose your discharge port wisely:

- Loop pipe for fluid-like paste.

- Wide-mouth (square port) for high-viscosity tahini.

If you're serious about producing high-quality tahini --- contact Furui Machinery today. We’ll help you select the right tahini making machine.

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat