Slurry Separator

Slurry separator is an effective solution for separating solid particles from liquid slurry, especially in animal waste management. By utilizing a screw-driven mechanism, this machine can reduce the liquid content to 55%-60%. There are three models of slurry separators for sale, with a processing capacity of up to 30 m³/h.

- Versatile to handle a wide range of materials, such as animal manure, biogas slurry.

- Allowing for consistent processing of slurry (using a pump and pipes).

- Low power consumption (physical pressing).

- Low maintenance rate.

Specifications of Slurry Separator

A slurry separator is widely used in industries dealing with organic waste, such as livestock farms, biogas plants, or slaughterhouses. Furui Machinery offers two models of screw slurry separators for sale, which use a mechanical process to separate solid and liquid from slurry mixtures.

What we supply:

- Screw separator (Available in three models: FR-180, FR-280, and FR-380)

- Pump and pipes

- Spare parts (screen/screw)

- Conveyor belt (optional)

- Electric control cabinet

Our slurry separators are adaptable to a wide range of applications. Contact us today, and let us tailor a solution that suits your business needs.

| Model | FR-180 | FR-280 | FR-380 |

| Motor Power | 4 kW | 5.5 kW | 11 kW |

| Pump Power | 3 kW | 4 kW | 5.5 kW |

| Dimensions (mm) | 1,950*920*1,330 | 2,150*940*1,330 | 2,300*1,100*1,700 |

| Weight | 430 kg | 650 kg | 1,060 kg |

| Processing Capacity | 7-8 m³/h | 15-18 m³/h | 25-30 m³/h |

| Screen | 180 mm | 280 mm | 360 mm |

| Inlet Diameter | 76 mm | 76 mm | 100 mm |

| Drain Pipe Diameter | 110 mm | 110 mm | 160 mm |

| Material | Carbon Steel + SS 304 Stainless Steel | ||

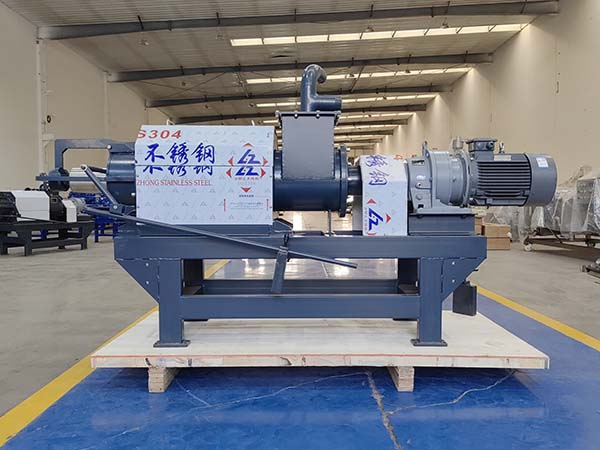

FR-280 Slurry Separator

FR-380 Separator

Screens of Different Models

Why Farms Use Slurry Separators?

1. Reduce Manure Handling and Storage Problems

Raw slurry is bulky, heavy, and difficult to manage. A slurry separator makes slurry manure into two manageable materials: solid and liquid. After separation,

- Solid volume is significantly reduced

- Liquid flows more easily through pumps and pipes, thereby directly lowering labor, transport, and storage costs.

2. Reduce Odor and Improve Farm Environment

Slurry separation reduces excess moisture in manure, keeping barns drier and cleaner. Dewatered solids limit bacterial growth and odor, improving air quality for both animals and staff.

3. Valuable End Products Instead of Waste

Separated solids can be used as bedding material, organic fertilizer, and more; While separated liquid can be used as liquid fertilizer or material for biogas system. Farmers can get extra interest from the dewatered products.

Applications Across Industries

- Livestock Farming: Efficiently manage animal manure by separating solids from liquids, reducing storage and disposal costs.

- Biogas Plants: Optimize biogas production by separating solids from biogas slurry, improving biogas yields.

- Wastewater Treatment: Treat wastewater from animal husbandry, industrial and municipal wastewater.

- Slaughterhouses & Meet Processing: Handle high-liquid-content waste such as blood, fat, and organic matter, ensuring efficient separation and disposal.

- Paper and Pulp Mills: Separate solids from paper pulp or sludge, reducing waste volume and enabling easier disposal of materials.

- Aquaculture: Manage waste from fish farms, separating solids from water to maintain clean and healthy aquatic environments.

Shipping to USA

Shipping to Spain

Slurry Separator to Austria

Dairy Manure Separator in Germany

Manure Separator in Bangladesh

Slurry Separator to Austria

Advantages of Slurry Separation

Using a slurry separator offers numerous advantages across various industries, particularly for livestock farms, slaughterhouses, biogas systems, and more.

1

Smaller Digester Volume

By removing solids, the liquid effluent entering digesters has a lower organic load. This means you can build smaller digesters-saving up to 300–400 m³ in volume for a 100-ton/day facility, thereby cutting construction, labor and land-use costs.

2

Better Solid Management

The separation of solids from liquids produces a more manageable solid fraction. The dewatered solids are easier to handle, transport, store and further process (e.g., dried or used as compost).

3

Odor Control

The dewatered solid emits less odor than liquid slurry, contributing to improved air quality and reducing complaints from nearby communities.

4

Prevent Digestor Issues

Removing solids upfront avoids crusting/floating layers in digesters. This eliminates downtime for manual scum removal and reduces maintenance costs. Besides, less solid waste entering the digester minimizes sludge buildup, extending the system’s operational lifespan.

5

Improved Biogas Production

Pre-treated liquid stays in anaerobic digesters long enough for microbes to efficiently break down organic matter, leading to higher methane yields and gas purity. Meanwhile, the dewatered solids can be repurposed as nutrient-rich organic fertilizer, creating more economic benefits.

6

Lower COD/BOD in Effluent

By separating solids from liquid manure before it enters the digester, the process reduces the organic load (COD and BOD) in wastewater. This leads to cleaner discharge, helping facilities meet environmental regulations and improve overall water quality.

Screen

Screw

Dewatered Cake

How Does Slurry Separator Work?

Our screw slurry separator is composed of a control cabinet, a motor, a reducer, a screen, a screw, a frame, a pipeline, etc.

It is widely used in many industries, such as wastewater treatment plants, slaughterhouses, paper mills, livestock farms, dairy farms, biogas slurry, and more.

Working Principle

When the slurry is pumped to the separator, a screw auger rotates and gradually pushes the slurry forward. Under increasing pressure, the liquid in the material is squeezed out of the screen and flows out of the drain pipe. At the same time, the solid material is retained and continuously transported to the discharge port. As the solid is concentrated, the pressure increases, pushing the discharge port open and squeezing out the solid. Generally, the water content of the dewatered solid is about 55%-60%. Here is a video for your reference.

Types of Mechanical Slurry Separators

Furui Machinery offers two types of mechanical slurry separators: screw press separators and inclined screen separators.

Inclined Slurry Separator

- How it works: The inclined slurry separator combines a vibration system, and screw press system, and automatic flushing system. The slurry is first passed over an inclined screen, where solid particles are captured while the liquid flows through and exits from the bottom. The separated solid materials are then further processed by the screw press to extract additional liquid.

- Applications: Commonly used for slurries with high liquid content, such as water-flushed manure, water-soaked manure, and wastewater treatment.

- Features: Made of 304 stainless steel, which ensures long-lasting durability and easy maintenance.

- Self-flushing system ensures that the screen remains clean and free of blockages during operation.

Conclusion

Our slurry separator employs a mechanical mechanism, which is ideal for dewatering animal manure, biogas slurry, wastewater treatment, and more. With over 15 years of global experience, Furui Machinery has become a trusted supplier of high-quality slurry separators.

Ready to upgrade your waste management system? Contact us now to discover how Furui Machinery’s slurry separators can save you time, money, and resources. Let us help you find the perfect solution for your needs!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat