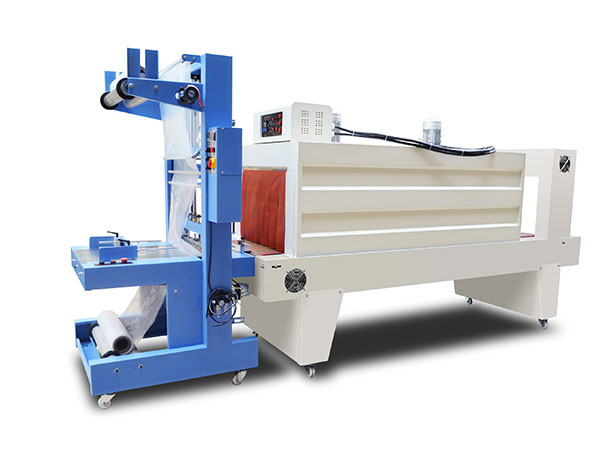

Shrink Tunnel Machine

Heat shrink tunnel machine is used in a wide range of industries to apply protective and aesthetic shrink film to products. At Furui Machinery, we offer different types of heat shrink machines with conveyors, which are compatible with different shrink films such as PE, PVC, PP, and POF.

- A variety of heated tunnels to suit different product sizes and applications;

- Conveyor speed ranges from 0-15 m/min, which is adjustable;

- Ideal for packaging in industries such as food, beverage, pharmaceuticals, and more;

- Can be used as a standalone unit or be integrated with other packaging equipment.

Heat Shrink Tunnel for Sale

Heat shrink tunnel is an essential packaging machine widely used across various industries. This machine applies a tight shrink film around products, protecting them from dust, moisture, dirt, and tampering. Furui Machinery offers a wide range of heat shrink tunnel machines with conveyors, catering to different packaging needs. These machines are designed to suit various product shapes and sizes, including boxes, bottles, cartons, trays, and more. Moreover, this machine can be used as a standalone machine or integrate with other packaging equipment. Please refer to the following tables for detailed specifications.

Small Shrink Tunnel Machine (PVC film)

| Model | BS-260 | BS-4020(B) | BS-4535(B) |

| Power | 2.8kW | 6kW | 8kW |

| Tunnel Size | 750*260*150mm | 800*400*200mm | 800*450*350mm |

| Speed | 0-12m/mim | 0-12m/mim | 0-12m/mim |

| Dimensions | 1,000*420*590mm | 1,200*610*830mm | 1,200*670*1,300mm |

| Weight | 35kg | 55kg | 70kg |

| Film | PVC | PVC | PVC |

- BS-4020 and BS-4535 are quartz infrared shrink tunnels. While BS-4020B and BS-4535B use iron tube heating.

- Suitable for packaging both regular and irregular items.

- Easy to operate and clean.

- Suitable film: PVC film

- Applications: Packaging boxes, toys, electronic products, books, CDs, hardware tools, cosmetics, daily necessities, beverages, fruits, etc.

Shrink Tunnels for Sale

Heat Tunnel Machine

Conveyor Belt and Cooling Fan

BS Series (POF/PVC/PP)

| Model | Power | Tunnel Size | Dimensions | Loading Weight | Machine Weight | Speed | Film |

| BS-4522LA | 7.5kW | 900*450*250mm | 1,200*650*1,100mm | ≦10kg | 90kg | 0-10m/min | PVC, POF, PP |

| BS-4535LA | 10kW | 1,200*450*350mm | 1,600*700*1,200mm | ≦30kg | 120kg | 0-10m/min | PVC, POF, PP |

| BS-6535LA | 13kW | 1,200*650*350mm | 1,600*900*1,200mm | ≦30kg | 180kg | 0-10m/min | PVC, POF, PP |

| BS-4522N | 10kW | 1,200*450*220mm | 1,600*660*1,350mm | ≦30kg | 140kg | 0-15m/min | PVC, POF, PP |

| BS-5530N | 15kW | 1,500*550*220mm | 1,900*900*1,500mm | ≦30kg | 180kg | 0-15m/min | PVC, POF, PP |

| BS-7530N | 18kW | 1,800*750*300mm | 1,900*900*1,500mm | ≦30kg | 350kg | 0-15m/min | PVC, POF, PP |

- Using stainless steel heating tubes with hot air recirculating system, providing over 15% energy savings.

- Adjustable shrink temperature and transmission speed to better meet packaging requirements.

- Air-jet shrink system makes it highly flexible to handle products of various shapes and sizes simply by adjusting the position and parameters of the jet device.

- Suitable for various shrink films PVC, POF, and PP. It is especially suited for shrink packaging using POF films.

- Applications: Widely used in food, beverage, hardware tools, daily necessities, chemical products, and other industries.

BS Heat Shrink Tunnel

BSE Shrink Tunnel Machine

BSE Series (PE, PVC, PP, POF)

| Model | Power | Tunnel Size | Dimensions | Loading Weight | Machine Weight | Speed | Film |

| BSE-4535 | 17kW | 1,300*450*350mm | 2,600*690*1,400mm | ≦15kg | 200kg | 0-15m/min | PE, PVC, POF, PP |

| BSE-5040 | 18kW | 1,500*500*400mm | 2,500*740*1,550mm | ≦35kg | 260kg | 0-15m/min | PE, PVC, POF, PP |

| BSE-6040 | 20kW | 1,800*600*400mm | 2,800*840*1,600mm | ≦35kg | 300kg | 0-15m/min | PE, PVC, POF, PP |

| BSE-7050 | 24kW | 1,800*700*500mm | 2,800*940*1,700mm | ≦35kg | 400kg | 0-15m/min | PE, PVC, POF, PP |

| BSE-5040A | 20kW | 1,200*450*220mm | 2,500*740*1,550mm | ≦35kg | 290kg | 0-15m/min | PE, PVC, POF, PP |

| BSE-5040A | 24kW | 1,800*600*400mm | 2,800*840*1,600mm | ≦35kg | 340kg | 0-15m/min | PE, PVC, POF, PP |

| BSE-7050A | 28kW | 1,800*600*400mm | 2,800*940*1,700mm | ≦35kg | 450kg | 0-15m/min | PE, PVC, POF, PP |

- Using stainless steel heating tubes ensures quick heating and long service life.

- Equipped with high-temperature resistant insulation curtain to greatly reduce heat loss;

- Customizable Conveyor Belt: including roller belt (chain belt), Teflon mesh belt, or stainless steel mesh belt to choose from.

- Suitable Films: PE, PVC, POF, PP

- Applications: packaging cans, glass bottles, beer, water bottles, wood, ceramics, household appliances, and computers.

Working Principle: The hot air generated by heating tube rotates at high speed through the two large impellers inside, making the hot air very uniform. Then, the high-speed rotating hot air is ejected from each hole in the inner tank of the machine, shrinking the objects passing through the furnace in all directions and quickly.

Optimizing Shrink Tunnel's Performance

Two key parts of a heat shrink wrap tunnel are conveyor belt and heating tunnel. The conveyor system smoothly transports products through the heating and shrinking zones. The heating tunnel applies heat to the shrink film wrapped around the products. The factors affecting your heat shrink tunnel's performance include shrink film (type, thickness), product size and shape, tunnel temperature, conveyor speed, airflow, etc. For more details, please feel free to reach out to us.

1. Conveyor Belt

- Stainless steel mesh belt is designed for packaging small items, such as cartons, stationery, and accessories, regardless of how irregularly shaped or randomly placed. However, it is not suitable for heavy items.

- Roller conveyor is primarily used for heavier and larger products.

- Teflon mesh conveyor belt is specifically designed for items requiring high shrink quality. It is also suitable for small and delicate items.

2. Temperature Control

Set optimal temperature according to the thickness of the packaging film, the speed of the conveyor belt, etc. If wrinkles appear after shrink wrapping, increase it by 5°C to 10°C, then wait 2-3 minutes to test again. On the other hand, if the shrink film cracks, lower the temperature and test again.

3. Conveyor Speed Control

Adjust the conveyor speed to allow sufficient dwell time for the film to shrink completely. If the tunnel temperature is low, reduce the conveyor speed to prolong the heating time.

4. Film Selection

Choose the right film compatible with your product type and shrink tunnel.

- PE Film: PE film is thick and often used for packaging beverages and bundling multiple products. Ideal for heavy-duty applications.

- POF/PVC Film: POF and PVC film offer a clear, high-quality finish and are commonly used for packaging cosmetics, gifts, phone cases, toys, electronics, and office supplies.

Shrink Wrapping Machine

Heat Shrink Machine

Benefits of Shrink Wrap Tunnel

Heat shrink machine is an indispensable tool in modern packaging, offering versatility and efficiency across a wide range of industries. Let’s take a closer look at its key benefits:

1. High Packaging Quality

Our machines deliver a tight and smooth finish that enhances the visual appeal, making items look more attractive.

2. Product Protection

Shrink wrap creates a tight, tamper-resistant seal that protects products from dust, moisture, and tampering during transport and storage.

3. Cost Savings

Shrink wrap can often be used in place of boxes, cartons, or other packaging materials, reducing material waste and lowering packaging costs.

4. Versatility

Our tunnel wrapping machines can handle a wide range of products in different sizes and shapes, from food items to electronics, beverages, cosmetics, and more. They can also work with various types of shrink film, such as PE, POF, and PVC. More importantly, our machine be customized for different products and packaging needs.

Conclusion

Heat shrink tunnels provide a reliable, efficient, and cost-effective packaging solution for various industries, including food and beverage, cosmetics, pharmaceuticals, and more. Furui Machinery, a professional packaging machine supplier, offers a diverse selection of shrink tunnel machines that are compatible with films like PE, PVC, POF, and PP. These machines can be used as standalone units or integrated into a packaging line, making them versatile for different production needs. If you are involved in the packaging business, a shrink wrap tunnel will be a worthwhile investment. Welcome to contact us for more details!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat