Shrink Film Machine

Shrink film machines play a crucial role in modern packaging, providing efficient, durable, and visually appealing solutions. Furui Machinery offers two series of plastic shrink wrap machines to meet diverse needs: the BS series, compatible with POF, PVC, and PP films, and the BSE series, which supports PE, PVC, PP, and POF films. Let’s take a closer look at the different types of plastic shrink film machines and their applications.

- PVC Shrink Film Machine

- POF Shrink Film Machine

- PE Shrink Film Machine

PVC Shrink Film Machine

PVC shrink film machines utilize polyvinyl chloride film. This type of film features remarkable puncture resistance and high tensile strength, making it ideal for wrapping various products ranging from beverages to electronics. While it is not as eco-friendly as POF, PVC film is often used in packaging for non-food items, such as toys, books, and cosmetic products. At Furui Machinery, all our shrink tunnels are compatible with PVC film.

Features:

- High Clarity and Gloss: PVC shrink films provide excellent transparency, enhancing the aesthetic appeal of packaged products.

- Cost-Effective: Generally more affordable than other types of shrink films, making it suitable for budget-conscious businesses.

- High shrink rate, which ensures a snug fit around products.

Applications:

- Food Industry: Commonly used to package items like bottled drinks and snacks.

- Cosmetics: Perfect for packaging cosmetics and personal care items where appearance matters.

- Pharmaceuticals: Used to seal medicine and products in tamper-proof packaging.

- Stationery: Suitable for wrapping office supplies, and electronics, ensuring a polished look.

POF Shrink Film Machine

POF shrink film machines use polyolefin film, a highly versatile material known for its clarity, strength, and environmental friendliness. POF films are safe for food packaging and widely used in industries such as pharmaceuticals, cosmetics, and electronics.

Features:

- High transparency and gloss, providing a professional finish.

- Non-toxic: Safe for direct food contact, making it suitable for food packaging.

- Heat/Cold Resistance: Can withstand a wide range of temperatures, making it suitable for various packaging environments.

- Eco-Friendly: Often made from recyclable materials, appealing to environmentally conscious consumers.

Applications:

- Food Packaging: Used to package baked goods, frozen foods, and fresh produce.

- Electronics: Ideal for protecting delicate electronic products during shipping.

- Retail goods: Suitable for packaging consumer products like toys and books.

- Cosmetics and Personal Care: Ideal for bundling products like shampoo, lotions, and other toiletry items.

PE Shrink Film Machine

PE shrink film machines use polyethylene film, which is highly durable and suitable for heavier loads. PE films are ideal for bundling larger items like bottles, cans, boxes, and cartons. It is commonly used in industrial applications for creating multi-packs or securing goods during transport. Our BSE series heat shrink tunnels can accommodate PE film while also being compatible with PVC and POF films.

Features:

- High Strength: Provides excellent puncture resistance and tear strength, ideal for heavy-duty applications.

- Cost-Effective: Generally more affordable for bulk packaging applications.

- Stretchable: PE film is more elastic, allowing it to stretch over larger, irregularly shaped items before shrinking.

- Less transparency compared to POF, but excellent for industrial use.

Applications:

- Bulk packaging: Ideal for wrapping large items such as pallets, bricks, and furniture.

- Beverage industry: Commonly used for multipacks of drinks, bottles, cans, and trays, providing secure bundling.

- Industrial goods: Suitable for protecting industrial parts and components, such as building materials, auto parts, and hardware, from dust and moisture.

Tips for Optimal Use of Shrink Film Machine

1. Choose the Right Film: Select the appropriate film type and thickness to match your machine and product requirements.

- For Small, Retail, or Food Products: POF is the best option due to its clarity, flexibility, and food-safe properties.

- For Non-Food Products with a High-Quality Finish: PVC shrink film is ideal for items where visibility and tamper-proof packaging are important.

- For Large or Heavy Items: PE shrink film is the top choice for wrapping large, bulky, or heavy products that require extra durability and protection.

2. Machine Type: If using a shrink bundler, you will use our PE shrink film machine (BSE series heat shrink tunnel). Both BS and BSE series heat shrink tunnels are suitable for use with PVC and POF shrink films, providing flexibility based on your packaging needs.

3. Temperature Settings: Different films require specific temperatures to achieve optimal shrinkage: PVC: 130-160°C; POF: 140-150°C; PE: 140-170°C. Ensure you set the correct temperature. Too high may damage products, while too low may result in shrinkage wrinkles.

4. Conveyor Speed: Adjust the conveyor speed to match the product size and type, ensuring an even shrink around the product for optimal packaging results.

Conclusion

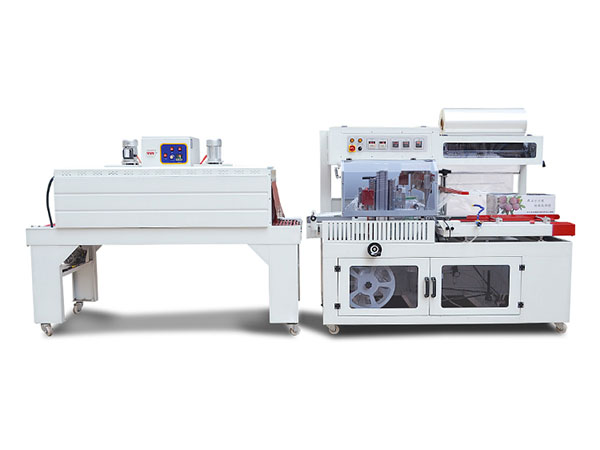

Furui Machinery provides a comprehensive range of plastic film shrink machines compatible with POF, PVC, PP, and PE films. Our shrink tunnels can operate independently or work with sealing machines or bundlers for more versatile packaging solutions. If you're considering purchasing a shrink film machine, please share details about the product you plan to package, its size, the type of film, and any specific packaging requirements. We will assist you in selecting the most suitable machine to meet your needs.

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat