Shrink Bundling Machine

Shrink bundling machine is designed to bundle multiple items together using a durable heat-shrink film. It consists of a sealing machine and a heat shrink tunnel. This machine is widely used for packaging products such as bottles, cans, boxes, trays, or other goods for transportation, storage, and retail display. Furui Machinery offers semi-automatic and fully automatic shrink wrapping systems, tailored to different production needs.

- Integrated with a production line for automatic feeding, film wrapping, sealing, cutting, shrinking, cooling, and shaping.

- A specially designed sealing knife that ensures a strong, clean seal without cracking or sticking to the blade.

- Flexible feeding platform options, available in both straight and L-shaped designs.

Shrink Bundling Machine

Shrink bundler machine is an efficient and cost-effective way to package items like bottled beverages, canned goods, or boxed items. It plays a crucial role in bulk transportation and retail display. Furui Machinery offers a range of shrink bundling systems designed to meet diverse packaging needs, ensuring both efficiency and quality. Please check the following details.

Applications:

- Beverage cans or bottles (e.g., multipacks of drinks)

- Boxes, cartons, or large, flat items (e.g., trays, tiles)

- Wood, steel, ceramics, auto parts, furniture, home appliances, electronics or accessories, hardware, and tools.

Automatic Shrink Bundling Machine

This shrink bundling system employs our FL series sealing machine and BSE series shrink tunnel. The system features a linear feeding mechanism that ensures smooth handling of products, making it adaptable to various item sizes without restrictions on length. The key features include:

- Customizable conveyor options: chain roller, Teflon mesh, or stainless steel mesh, depending on customer requirements;

- Suitable for PE film packaging;

- The feeding conveyor belt can be designed as L-shaped feeding;

- Stepless mechanical speed regulation to adjust the speed of the conveyor belt.

Below are more parameters for your reference.

| Model | FL-6540AF | FL-7030AF | FL-7540AF |

| Voltage | 220V 50/60HZ | 110/220V 50/60HZ | 220V 50/60HZ |

| Power | 2KW | 2KW | 2.5KW |

| Size | 500*400mm | 700*300mm | 600*400mm |

| Feed height | 825±25mm | 850±50mm | 825±25mm |

| Sealing temperature | 0-300°C | 0-300°C | 0-300°C |

| Speed | 15m/min | 15m/min | 15m/min |

| Weight | 380kg | 465kg | 520kg |

| Dimensions | 1.05*1.05*2.05m | 1.65*0.92*1.895m | 1.15*1.05*2.05m |

| Model | BSE-6040A | BSE-7050A |

| Voltage | 220V/380V 50HZ | 220V/380V 50HZ |

| Power | 24kW | 28kW |

| Packaging size | 550*450mm | 600*450mm |

| Tunnel size | 1800*600*400mm | 1800*700*500mm |

| Speed | 0-15m/min | 0-15m/min |

| Weight | 470kg | 550kg |

| Dimensions | 2500*820*1680mm | 2800*1050*1650mm |

| Suitable films | PE, POF, PVC, PP | PE, POF, PVC, PP |

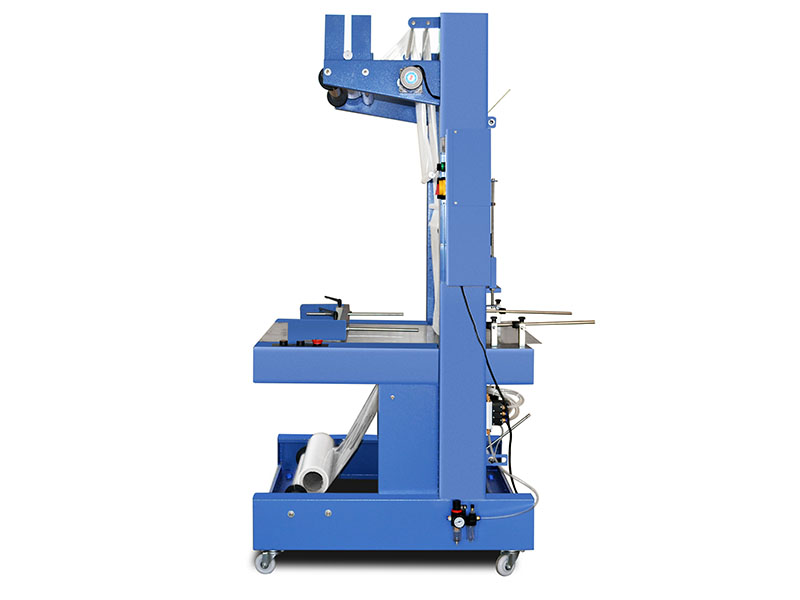

Semi-automatic Shrink Bundler

The semi-automatic sleeve bundler is an economical packaging machine that is simple and convenient to operate. This machine is suitable for packaging individual items or bundling multiple items together.

- Automatic film feeding, sealing, and cutting;

- Choose manual or automatic material feeding according to your needs;

- The feed fixing frame can be adjusted according to different product specifications;

- Suitable for packaging of multiple combinations of products with or without a bottom tray;

- Suitable for PE shrink film.

| Model | FL-6540 | FL-7540 | FL-5038 |

| Voltage | 110/220V 50/60HZ | 110/220V 50/60HZ | 110/220V 50/60HZ |

| Power | 1.5kW | 1.5kW | 1.8kW |

| Packaging Size | 400*400*380mm | 500*500*380mm | 450*270*350mm |

| Speed | 5-8/min | 5-8/min | 5-8/min |

| Weight | 300kg | 350kg | 380kg |

| Dimensions | 925*940*1920mm | 925*1040*1920mm | 1020*830*1980mm |

| Suitable film | PE | PE | PE |

| Model | BSE-6040A | BSE-5040A |

| Voltage | 220V/380V 50HZ | 220V/380V 50HZ |

| Power | 24kW | 20kW |

| Packaging size | 550*450mm | 450*400mm |

| Tunnel size | 1800*600*400mm | 1500*500*400mm |

| Speed | 0-15m/min | 0-15m/min |

| Weight | 470kg | 290kg |

| Dimensions | 2500*820*1680mm | 2500*740*1550mm |

| Suitable films | PE, POF, PVC, PP | PE, POF, PVC, PP |

Working Principle of Shrink Bundling Machine

- Product Arrangement: Products like water bottles, canned drinks, or boxed goods are grouped together.

- Film Wrapping and Sealing: Sensors detect the product's position, and then the machine automatically wraps shrink film around the products. The sealing mechanism performs, wrapping the product tightly in the film.

- Heat Shrinking: The wrapped products pass through a heat shrink tunnel, where the film shrinks and adheres tightly to the product surfaces, securing them in place.

- Cooling and Shaping: After the heat shrink process, the bundled package is cooled in the cooling zone. This cooling helps the film set and conform tightly to the product, resulting in a smooth, transparent package. Finally, the completed package is conveyed out of the machine.

Shrink Bundler

Bundling Shrink Machine

Advantages of Using Shrink Bundler

- Ease of Transport: By bundling multiple products into a single, compact package, shrink bundling machines make transportation and storage easier.

- Cost Savings: Compared to traditional cardboard packaging, using shrink film is more economical, reducing the cost of packaging materials.

- Transparent Display: Shrink film is typically transparent, allowing consumers to see the products inside. This visibility enhances product presentation and can aid in sales promotion.

- Versatile Adaptability: The machine can accommodate various product shapes and sizes, such as bottles, boxes, and cans.

Conclusion

Overall, shrink bundler machine is a versatile and cost-effective packaging solution. Whether you need to package beverage cans, bottles, boxes, or trays, this machine is an ideal option. At Furui Machinery, we offer a variety of shrink bundling systems, automatic or semi-automatic, tailored to meet your specific needs. If you're interested, don’t hesitate to contact us for further information. We’re here to assist you!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat