Screw Press Dewatering Machine

Screw press dewatering machine is a piece of solid liquid separation equipment widely used across various industries. Furui Machinery offers a range of continuous screw press with processing capacities ranging from 0.2 to 40 tons. In addition, we also provide customized solutions tailored to the specific characteristics of the materials you need to process.

- Widely used in various industries, including agricultural waste management, food industry, etc.

- Different screw designs to choose from, single or twin screw press, and tapered screw press.

- Various test videos or videos of customer feedback for reference.

Dewatering Screw Press for Sale

Screw press dewatering machine is an efficient solid-liquid separator, which can effective reduce the liquid content to about 60% by using a screw press mechanism.

Furui Machinery offers a diverse range of screw press machines designed to meet various dewatering needs. We've helped numerous clients with their projects, including dewatering spent grains, processing shredded coconut or waste fruit and vegetable, extracting juice, dewatering seafood, and more.

Additionally, the machine can serve as a stand-alone unit or be integrated with conveyor belts or other equipment to create a complete production line.

FR-260 Screw Press

FR-420 Screw Press Machine

| Model | FR-0.5-180 | FR-260 | FR-350 | FR-420 | FR-500 | FR-550 | FR-630 | FR-870 |

| Processing Capacity | 0.2-0.5 t/h | 1 t/h | 2 t/h | 3-4 t/h | 5-6 t/h | 8-10 t/h | 15-18 t/h | 30-40 t/h |

| Screw Diameter | 180mm | 260mm | 350mm | 420mm | 500mm | 550mm | 630mm | 870mm |

| Screw Speed (r/min) | 5-15 | 5-15 | 5-15 | 5-15 | 5-15 | 5-15 | 5-15 | 5-15 |

| Hydraulic Power | - | - | - | 1.1 kW | 1.1 kW | 1.1 kW | 2.2 kW | 3 kW |

| Motor Power | 3-4 kW | 5.5-7.5 kW | 7.5-11 kW | 11-15 kW | 15-18.5 kW | 22 kW | 30 kW | 45 kW |

| Dimensions (m) | 1.8*0.55*0.92 | 2.2*0.7*1.2 | 3.38*0.9*1.45 | 4.28*1*1.75 | 5.105*1.2*2.05 | 5.22*1.22*2.15 | 5.8*1.3*2.25 | 6.8*1.53*2.475 |

| Weight | 450 kg | 900 kg | 1,300 kg | 2,600 kg | 3,050 kg | 3,550 kg | 4,300 kg | 7,400 kg |

- FR-420 to Sri Lanka

- Screw Press Dewatering Machine to Canada

- FR-180 to Malaysia

Materials Can Be Processed

| Material Type | Typical Materials | Uses of Dewatered Solids |

| Food Waste & Fruit/Vegetable Waste | Kitchen waste, restaurant leftovers, fruits & vegetable scraps | Volume reduction; solids used for organic fertilizer or biomass fuel |

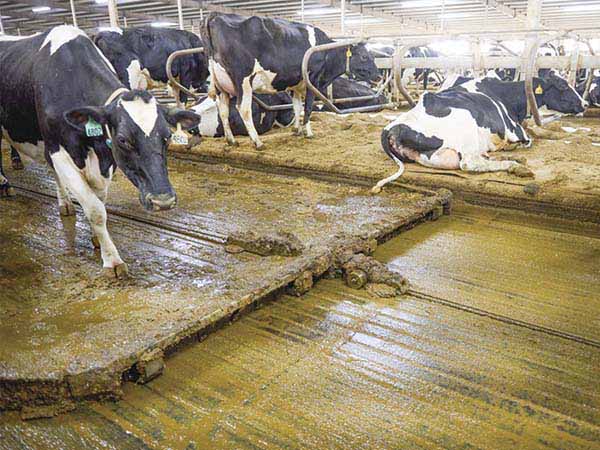

| Livestock Manure | Cow dung, pig manure, chicken manure | Dewatered solids used for organic fertilizer production or biogas feedstock |

| Agricultural Residue | Corn cobs, rice straw, sugarcane bagasse | Dewatered solids used for animal feed or biomass power generation |

| Distiller’s & Vinegar Grains | Beer lees, rice wine residue | Used as animal feed ingredients after dewatering |

| Coffee & Tea Residue | Coffee grounds, tea leaves | Dewatered solids used for deodorizer or soil conditioner |

| Wood Chips & Sawdust | Sawdust, wood chips | Reduced moisture for biomass pellet fuel production |

| Coconut Coir & Palm Fiber | Coconut husk fiber, palm fiber | Used in board manufacturing after dewatering |

| Pulp & Textile Fiber | Waste paper pulp, cotton pulp | Fiber retained after dewatering; reused for recycled paper production |

| Seaweed & Aquatic Plants | Algae, water grass | Used as feed additive or biomass energy source after dewatering |

Applications of Screw Press Machine

Screw press dewatering machine is widely used across various industries.

Dewatering Spent Grains

Spent grains from breweries and distilleries can be dewatered and repurposed for animal feed or other uses.

Paper Pulp Dewatering

Used in the paper industry to remove excess water from pulp to improve the quality of final paper products.

Agricultural Waste Management

1. Manure management. Used to separate liquid and solid components in animal manure.

2. Dewatering organic waste, such as straw, wood chips, sawdust, coffee grounds, coconut shells, and more.

Plastic Dewatering

Screw press machine can remove water or moisture from plastic materials, which is necessary for further processing, such as drying, pelletizing, or molding.

Food Industry

In the food processing industry, the screw press is used for juice production.

It also plays a crucial role in food waste treatment, such as fruit & vegetable waste, seafood waste, and more.

Demo Test Videos

Advantages of Screw Press Machine

Continuous Operation

Designed for high efficiency, the machine is capable of processing large volumes of material continuously.

Various Applications

The screw press machine is highly versatile, suitable for a wide range of materials across various industries.

Custom Design

Furui Machinery offers tailored options to better meet your needs, including screw design, screen opening size, machine material.

Moisture Reduction

Low Operating Costs

Screw press machine adopts mechanical compression method to remove moisture, no need for external heat sources, making it more cost-effective.

Flexibility in Integration

Our dewatering screw press can be used as a stand-alone unit or integrated into a production line with other equipment, like conveyor, trash can lifter.

No Chemical Additives Needed

The dewatering process does not require the addition of flocculants or other chemicals, which can lower environmental impact at the same time.

Compact Structure

The screw press extruder has a compact structure design. It requires a small footprint and is suitable for various site conditions.

Tapered Screw

Screw Press With Conveyor

Screw Press Machines for Sale

Dewatering Screw Press Design

Single Scerw Press

- The single screw press is designed with a single screw that compresses the material as it moves through the press.

- Material is compressed against the screen by the screw to extract liquid.

- Single screw press is suitable for solid-liquid separation of materials with a small amount of fiber or sticky materials.

Twin Scerw Press

- The twin screw press features two screws that rotate in opposite directions to compress the material, which offers enhanced efficiency.

- Additional pressure generates as the material is compressed between the screws.

- More versatile in handling materials that are tough or have a high moisture content.

Tapered Scerw Press

- The screw in a tapered screw press starts with a larger diameter at the feed end and gradually narrows to discharge end.

- As the screw diameter decreases, the space between the screw and the screen narrows, progressively increasing the pressure applied to the material.

- Tapered screw press is effective in applications in dewatering of fibrous materials, sludge, or biomass waste.

Main Parts of Screw Press Machine

1. Screw

- Screw Shaft: The screw shaft is the core component of the screw press.

- Blades: The shape, pitch, and angle of the blades are tailored to control material conveyance speed, compression force, and retention time within the press. For example, for high-fiber materials, a larger screw pitch is used to prevent clogging and apply uniform pressure.

2. Screen:

- The opening sizes of the screen are customized based on the particle size and separation requirements.

- Ease of Maintenance: Designed to be disassembled for easy cleaning and maintenance.

3. Transmission System

- Motor and Gear Reducer: A high-quality motor paired with an appropriate reducer adjusts the screw shaft's speed to control material handling and compression levels.

- Robust Connections: Components are securely connected with strong seals to minimize energy loss and reduce the risk of mechanical failures.

Choosing the Right Screw Dewatering Machine

When selecting a screw press dewatering machine, consider the following factors:

-

Material Characteristics: It is important to choose a machine that can handle the specific materials you will process. Welcome to talk with us for more details.

-

Processing Capacity: Assess the volume of material you need to process. Furui Machinery offers various models to suit different capacity requirements.

- Automation Level: The screw press can function as a standalone unit or as part of a production line. We also offer conveyor belts, trash can lifters, and additional equipment to enhance your production line's automation.

At Furui Machinery, we offer a range of customized dewatering solutions tailored to your specific needs. Please contact us today for more details!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat