Powder Pouch Packing Machine

Powder pouch packing machine is an automated packaging system designed to fill and seal pouches or bags with powder products. Operating in a vertical orientation, this machine combines several key functions — bag forming, powder filling, sealing, and cutting.

- Capable of handling a wide range of powder materials, including spices, coffee, flour, tea, detergents, paints, and more.

- A spiral screw mechanism (auger filling) is used to accurately transport powder into pouch;

- Can be equipped with optional features like a gas flushing system and coding machine, based on your specific needs.

Powder Filling and Sealing Machine

Vertical powder packing machine is one of the hot-selling products of Furui Machinery. This machine utilizes an auger filling mechanism to precisely measure and transfer powders. It operates in a vertical orientation where the pouch is formed, filled, and sealed in a continuous, vertical motion. It is suitable for filling powders into various pouch styles, such as pillow bags, stand-up pouches, and gusseted pouches.

Applications:

- Food Industry: packaging products such as milk powder, coffee, tea powder, spices, flour, sugar, seasoning, etc.

- Pharmaceutical Industry: packing nutritional supplements, herbal powders, and powdered medicines;

- Chemical Industry: Used for packing laundry detergent powder, cleaning powder, paints, adhesives, etc.

- Cosmetics Industry: For packaging powders used in makeup, talcum powder, dry shampoo, and other personal care products.

Key Components:

- Vertical Powder Packaging Machine: The core of the powder filling and sealing system, is responsible for forming, filling, sealing, and cutting the pouches. It contains film feeding system, forming unit, measuring system, sealing and cutting mechanism, and PLC control system.

- Auger Filling Machine: The auger filling system is responsible for accurately measuring the packaging weight of each pouch. It works by using the number of turns of the screw to control the amount of powder dispensed.

- Screw Feeder: Transports powder to the filling head with consistent flow and precision. It uses dual motors — one for feeding and one for vibration — to independently control the powder flow. In addition, you can choose square or round hoppers depending on your specific needs.

- Conveyor: Automatically transfers the packed pouches to the next stage. It is equipped with a high-quality micro motor, which ensures low noise and long service life. The conveyor helps reduce product waste and ensures a smooth workflow during the packaging process.

| Model | VFFS-320 | VFFS-420 | VFFS-520 |

| Film width | Max.320mm | Max.420mm | Max.520mm |

| Bag width | 25-145mm | 80-200mm | 110-250mm |

| Bag length | 30-150mm | 50-300mm | 80-400mm |

| Sealing type | 3-side seal, back seal, 4-side seal | ||

| Film roll diameter | Max.320mm | Max.320mm | Max.320mm |

| Packing rate | 20-70 bags/min | 5-60 bags/min | 5-50 bags/min |

| Power | 220V 50Hz/2.2kW | 220V 50Hz/3kW | 220V 50Hz/4kW |

| Dimensions | 650*1,050*1,450mm | 1,110*1,050*1,290mm | 1,110*1,675*1,655mm |

| Weight | 350kg | 400kg | 500kg |

Features of Powder Pouch Packing Machine

Integrated Automation

The machine seamlessly combines several packaging functions: bag forming, measuring, filling, sealing, cutting, coding, and counting. This automation reduces human labor and minimizes the potential for errors, resulting in faster and more consistent packaging.

Servo-Controlled Film Feeding System

Our powder pouch packing machine uses a servo motor system and a color mark sensor for precise film positioning, ensuring accurate and consistent packaging with an attractive finished product.

Flexible Pouch Design

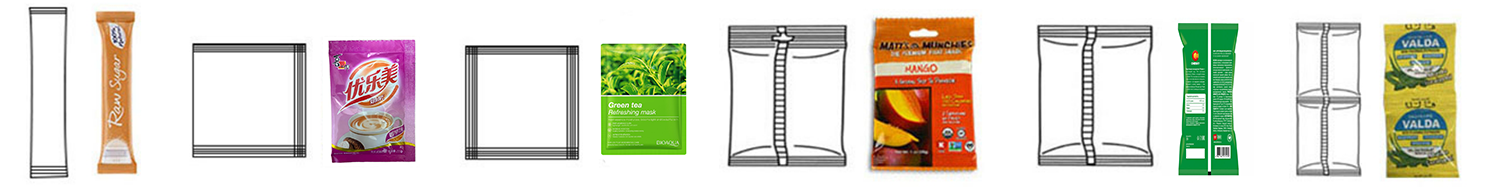

This machine supports a variety of pouch styles, including pillow bags, corner seal pouches, hole-punched bags, and chain bags, allowing flexibility in packaging options. It can be equipped with various sealing blade designs, such as straight tooth, mesh cutting, wave tooth, etc.

PLC Control System

This PLC control system allows for continuous adjustment of any parameters during the packaging process without requiring a machine shutdown, providing greater flexibility and minimizing downtime.

Versatile Filling Mechanism

The machine can be adapted to different powders with varying densities, flow properties, and particle sizes, by changing the filling head.

Dust Control

The packing machine features a closed structure, significantly reducing noise levels and preventing powder dust from escaping.

Conclusion

The vertical powder pouch packing machine is a highly effective and versatile solution for packaging a wide range of powdered products. With its advanced technology, precise filling system, customizable features, and ease of use, it ensures efficient, high-quality packaging. Whether for food, pharmaceuticals, or chemicals, this machine offers significant advantages in terms of efficiency, flexibility, and ease of use, making it a key piece of equipment in modern production lines. Furui Machinery offers various designs of FFS machines for powders, granules, paste, and liquid. Welcome to contact us for more details!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat