Pineapple Juice Machine

Designed specifically for high-fiber and high-moisture fruits, the Furui Machinery pineapple juice machine delivers stable, high-yield juice extraction with minimal clogging and downtime. Using an optimized industrial screw press structure, it efficiently separates juice from pulp — ensuring consistent performance in continuous commercial production.

- Capable of handling 0.5 to 2.5 tons per hour.

- Suitable for: pineapple, grapes, ginger, apples, carrots, berries, tomatoes, leafy greens, and more.

- Operate as a standalone unit or be integrated into a complete juice production line.

- Contact parts are made from food-grade stainless steel, ensuring hygiene and durability.

Specifications of Pineapple Juicer Machine

Pineapple is a high‑fiber, high‑acid fruit that is difficult to process efficiently. You may struggle with low juice yield, clogging during operation, and time‑consuming cleaning. As an experienced industrial juice machine manufacturer, Furui Machinery provides two series of pineapple juicer machines engineered specifically for continuous, high‑efficiency extraction of fibrous fruits.

- LZ Series --- For processing crushed pineapple pieces;

- PZJ Series --- With integrated crusher, capable of processing whole pineapples directly.

Our screw extractor is engineered for high efficiency, effectively squeezing out juice while separating the pulp. With a capacity ranging from 0.5 to 2.5 tons, it is ideal for both small and medium-sized operations. Below are more parameters for your reference.

LZ Series

| Model | Capacity | Power | Dimensions |

| LZ-0.5 | 0.5 t/h | 1.5 kW | 910*385*810mm |

| LZ-1.5 | 1.5 t/h | 4.0 kW | 1,300*500*1,330mm |

| LZ-2.5 | 2.5 t/h | 11 kW | 1,480*740*1,780mm |

LZ Series Juicer

PZJ Series (With Crusher)

| Model | Capacity | Power | Dimensions |

| PZJ-0.5 | 0.5 t/h | 2.05 kW | 910*500*1,250mm |

| PZJ-1.5 | 1.5 t/h | 6.5 kW | 1,300*650*1,380mm |

| PZJ-2.5 | 2.5 t/h | 12.5 kW | 1,500*700*2,000mm |

Capacity Selection Tip: 1 ton of fresh pineapple typically yields 600-800 kg of juice, depending on fiber content and processing method. Select machine capacity based on daily output requirements and operating hours. Or contact us for more details!

PZJ Series Juicer

Which Pineapple Juicer Is Right for Your Project?

LZ Series – For Pre‑Crushed Pineapple Processing

The LZ series screw press juicer is designed to process peeled and pre-crushed pineapples, delivering high juice yield for commercial production.

Recommended if you:

-

Operate a large-scale production line and can use a separate crusher for pineapples

-

Want precise control over particle size before juicing to maximize juice extraction

-

Prefer a more cost-effective solution compared to integrated machines

PZJ Series – With Crusher

The PZJ series combines crushing and juicing in one machine, processing peeled pineapples directly. It is an ideal solution for those who want a single machine to handle the entire juicing process.

Recommended if you:

-

Prefer a compact solution without purchasing a separate crusher

-

Want to simplify operation and reduce labor requirements

Pineapple Juicer with Washing Machine

PZJ Juicer Machine

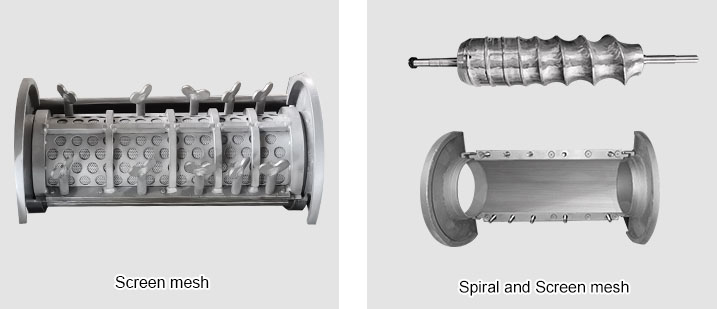

The primary component of the juicer is the tapered screw, designed with an increasing diameter and decreasing pitch towards the outlet. Additionally, the equipment includes front support, feed hopper (with or without a crusher), filter screen, casing, juice outlet, rear support, slag discharge outlet, motor, and more. Constructed from stainless steel, this juicer ensures durability and hygiene.

Applications of Pineapple Juicer

In addition to pineapple, this industrial screw press juicer is suitable for a wide range of fruits and vegetables, including:

- Apples, pears, grapes, berries

- Tomatoes, carrots, celery, wheatgrass

- Ginger, beet, and other fibrous materials

For citrus fruits such as oranges and lemons, Furui Machinery also provides dedicated industrial citrus juicers.

How to Extract Pineapple Juice?

1. Preparation

Wash the pineapples and then remove the skin and core. You can do this manually or use a peeling machine. Then crush the pineapples into small pieces.

Equipment Used: Washing machine, Peeling and coring machine and Curshing machine

2. Juicing

Feed the crushed pineapple pieces into the screw press juicer. As the screw mechanism rotates, the decreasing volume in the chamber applies pressure to the pineapples, squeezing the juice out. The juice will flow through a liquid outlet into a collection container, while the solid pulp will be expelled from another outlet.

3. Further Processing

If desired, further filter the juice to remove any remaining pulp or particles. And then store the extracted pineapple juice in clean, sterilized containers.

User Tips for Pineapple Juicer

When using a screw press juicer to process hard or fibrous fruits and vegetables, such as pineapples and ginger, consider the following tips:

-

Peel and chop hard fruits and fibrous vegetables before juicing to enhance extraction efficiency.

-

Keep the juicer stable during operation; avoid tilting or moving the machine.

-

Adjust the juicing speed properly when processing hard or fibrous items to prevent potential damage to the machine.

-

After juicing, thoroughly clean the machine to remove any leftover pulp for future use.

Conclusion

Furui Machinery's industrial pineapple juice machine is designed for large-scale extraction of juice from pineapples, with a processing capacity ranging from 0.5 tons to 2.5 tons per hour. This makes it an ideal solution for commercial juice production, ensuring high throughput and quality.

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat