Peanut Roaster Machine

As a leading manufacturer of peanut processing equipment, Furui Machinery offers advanced peanut roaster machine for sale designed for precision, consistency, and high-volume performance. Our roasting solutions cater to businesses of all sizes, ensuring optimal results for commercial and industrial applications.

- Rotary Peanut Roaster: With a 100 to 600 kg/h processing capacity, for batch roasting, this roaster is ideal for small to medium-scale operations.

- Belt Peanut Roaster: Designed for high-volume production, this roaster supports capacities from 500 to 2000 kg/h, ensuring continuous, automated roasting for large-scale manufacturers.

Peanut Roaster for Sale

A peanut roaster machine is designed to roast peanuts at controlled temperatures to enhance their flavor, texture and shelf life. This equipment is widely used in the production of roasted peanut snacks, peanut butter, peanut-based confectionery, and oil extraction.

In addition to peanuts, our industrial nut roasters can handle:

- Almonds, cashews, pecan, pistachio, and hazelnuts;

- Sunflower seeds, sesame seeds, pumpkin seeds, and coffee beans;

- Chickpeas, soybeans, broad beans, and other small-sized grains.

Role of Industrial Peanut Roaster Machine

- Enhances Flavor & Texture: Ensures uniform roasting, preserving the nut’s natural oils and taste.

- Increases Shelf Life: Roasting removes moisture, preventing mold and extending storage time.

- Improves Production Efficiency: Automated roasting reduces labor costs and ensures consistency.

1. Drum Peanut Roaster - For Batch Processing

Processing Capacity: 100-600 kg/h

| Model | Motor Power& Heating Power |

Drum | Capacity (per batch) |

Dimensions | Weight |

| DHL-1/QHL-1 | 1.1kW+22.5kW | 1 | 100kg | 2,900*1,400*1,650mm | 700kg |

| DHL-2/QHL-2 | 2.2kW+44kW | 2 | 200kg | 2,900*2,100*1,650mm | 1,200kg |

| DHL-3/QHL-3 | 3.3kW+66.5kW | 3 | 300-400kg | 2,900*3,020*1,650mm | 1,600kg |

| DHL-4/QHL-4 | 4.4kW+88kW | 4 | 400-500kg | 2,900*3,850*1,650mm | 2,000kg |

| DHL-5/QHL-5 | 5.5kW+112.5kW | 5 | 500-600kg | 2,900*4,700*1,650mm | 2,400kg |

Drum Nut Roaster

Features:

- Multiple Heating Options: Compatible with various heat sources, including coal, electricity, and gas, providing flexibility for different production needs.

- Adjustable Temperature Control: Room temperature to 300°C, adaptable to different roasting requirements.

- Advanced Heating Technology: Utilizes a rotary drum system combined with heat conduction and heat radiation for uniform roasting.

- Roasting temperature and time can be customized based on the specific product requirements.

- Simple operation and easy maintenance, making it ideal for commercial and industrial applications.

Commercial Nut Roaster

Peanut Roasting Machine With Conveyor

Single-Cylinder Nut Roaster

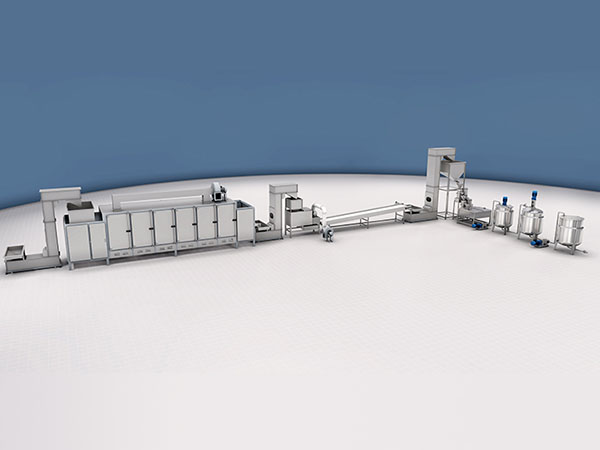

2. Continuous Peanut Roasting Machine

Processing Capacity: 100-2,000 kg/h

Furui Machinery’s belt peanut roaster machine is a continuous drying and roasting system designed for bulk production. It adopts a multi-layer hot air circulation system to maximize heat utilization and ensure uniform drying and roasting. This machine is ideal for processing nuts, dried fruits, herbs, and vegetables.

- Uses a "S"-shaped multi-layer conveyor system, allowing materials to be roasted gradually.

- Supports electric heating, gas heating, and other heat sources to accommodate different production needs.

- Utilizes advanced hot air circulation technology, with adjustable temperature control between 50°C and 160°C.

- Integrated cooling system allows products to cool immediately after roasting.

- Maintains the original color, texture, and nutritional value of the materials.

Belt Peanut Roaster

Material specifications:

- Food-contact parts: Made of 304 stainless steel for hygiene and durability.

- Casing: Constructed with 201 stainless steel for corrosion resistance.

- Frame: Built with carbon steel, ensuring structural strength and long service life.

Here is the standard vision. The material can be customized according to your requirements.

Continuous Peanut Roaster

Nut Roaster to Finland

Shipping Nut Roaster

Applications of Peanut Roasters

Industrial peanut roasters are used across various industries, including:

- Snack Manufacturing: Roasted peanuts are a key ingredient in many snack products.

- Peanut Butter Production: Roasting peanuts enhances flavor and texture, making them ideal for peanut butter manufacturing.

- Food Processing: Roasted peanuts are used in various processed foods, including energy bars, candies, and baked goods.

- Peanut Suppliers or Exporters: Many businesses that sell peanuts in bulk for retail or wholesale depend on industrial peanut roasters for consistent product quality.

Rotary VS Belt Peanut Roaster

Each type of peanut roasting machine has unique advantages, making them suitable for different production needs. Below is a detailed comparison:

| Items | Rotary Peanut Roaster | Belt Peanut Roaster |

| Working Principle | Uses a rotating drum for even roasting through heat conduction and radiation. |

Uses multi-layer hot air circulation with a conveyor system for uniform drying and roasting. |

| Processing Capacity | 100-600 kg/h | 100-2000 kg/h |

| Production Mode | Batch processing – requires loading and unloading after each cycle. | Continuous processing – materials move through multiple layers for seamless roasting. |

| Roasting Time (Peanuts) | About 40 minutes for each batch. | Less than 30 minutes from feeding to discharging. |

| Cooling System | No built-in cooling; equipped with cooling belt separately. | Integrated cooling zone after roasting. |

| Best For | Small to medium-scale businesses with batch processing needs. | Large-scale, high-volume production requiring continuous operation. |

| Applications | Nuts, coffee beans, sunflower seeds, and more. | Nuts, dried fruits, vegetables, herbs, and more. |

| Equipment Cost | Cheaper due to simpler design and smaller capacity. | Higher cost due to more complex automation and larger capacity. |

With Continuous Roaster

With Drum Roaster

How to Choose Peanut Roaster Machine?

When selecting a peanut roasting machine, several key factors should be considered:

1. Type of Raw Materials

The rotary peanut roaster is best suited for roasting nuts, beans, seeds, and kernels, including peanuts, sunflower seeds, almonds, chestnuts, and broad beans. In addition to roasting nuts and seeds, the belt roasting machine is also ideal for processing dried fruits, herbs, and vegetables, making it suitable for businesses with diverse roasting requirements.

2. Budget Considerations

- A rotary nut roaster is generally more affordable, making it an excellent choice for small to medium-sized businesses.

- A belt roaster requires a higher investment but it is fully automated, significantly reducing labor input and increasing efficiency.

3. Required Roasting Quality

Both drum and belt peanut roasters ensure even roasting and consistent quality. However, the belt roaster can better preserve the original color, texture, flavor, and nutritional value of the materials. Therefore, if you require higher quality of roasted nuts, the belt roaster will be a better choice.

4. Production Capacity and Processing Mode

- If your business operates on a batch-based system and handles moderate production volumes (100-600 kg/h), the rotary roaster is a suitable choice.

- If you require continuous, high-volume processing (500-2000 kg/h) with minimal downtime, the belt roaster is the better option, as it streamlines production and reduces manual handling.

Conclusion

At Furui Machinery, we take pride in our professionalism and expertise as a leading manufacturer in the peanut processing equipment industry. Our team is here to guide you in selecting the perfect peanut roaster to meet your specific needs. Contact us today to learn more about our peanut roaster and find the perfect solution for your needs.

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat