Manure Dewatering Machine

Manure dewatering machine is designed to separate solid and liquid components from animal manure, widely used in processing cow dung, pig manure and chicken manure. Furui Machinery has been selling manure dewatering machines since 2011. In 2023, our manure screw press was fully upgraded and three models are currently on sale. To date, we have provided our products to over 1,000 customers all over the world.

- 20 years of industry experience.

- Suitable for processing cow dung, pig manure, and chicken manure.

- Lots of test videos and customer videos for your reference.

- Related spare parts are available.

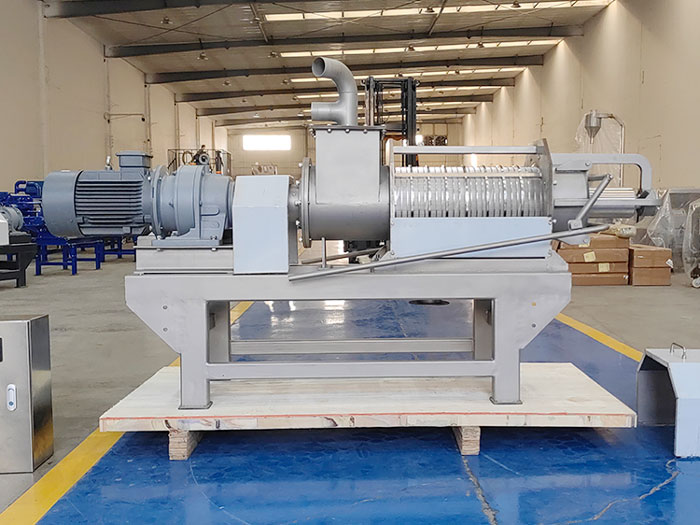

Specifications of Manure Dewatering Machine

Furui Machinery offers 3 models of screw manure dewatering machines for sale to meet different needs. The FR-180 model can efficiently process chicken manure, pig manure, and cow dung. On the other hand, the FR-280 and FR-380 models are suitable for larger-scale operations but are not recommended for broiler manure. In addition, we also provide a fully stainless steel version to choose from. Welcome to contact us for more details!

- Suitable for processing cow dung, chicken manure, pig manure, rabbit manure, and other animal waste;

- The water content of dewatered manure can be reduced to 55%-60%;

- Voltage, screen opening size, etc., can be adjusted;

- Own factory, with ready stock available for quick shipping;

- Customization is available according to your specific needs.

| Model | FR-180 | FR-280 | FR-380 |

| Motor Power | 4 kW | 5.5 kW | 11 kW |

| Pump Power | 3 kW | 4 kW | 5.5 kW |

| Dimensions (mm) | 1,950*920*1,330 | 2,150*940*1,330 | 2,300*1,100*1,700 |

| Weight | 430 kg | 650 kg | 1,060 kg |

| Processing Capacity | 7-8 m³/h | 15-18 m³/h | 25-30 m³/h |

| Screen | 180 mm | 280 mm | 360 mm |

| Inlet Diameter | 76 mm | 76 mm | 100 mm |

| Drain Pipe Diameter | 110 mm | 110 mm | 160 mm |

| Material | Carbon Steel + SS 304 Stainless Steel | ||

3D Drawing

Layout of Manure Dewatering Machine

Upgraded Manure Dewatering Machine in 2023

- The new machine adopts a larger and thicker frame, making it more sturdy.

- The motors and reducers we use are purchased from well-known Chinese brands (or Siemens) to ensure the stability and service life of the machine.

- The updated version is equipped with lifting rings and handles for easy transportation and installation.

Shipping to Spain

Slurry Separators to Germany

Shipping to Austria

Stainless Steel Manure Dewater Machines

Manure Screw Press for Sale

Manure Dewatering Screw Press

Customer Feedback

This video was taken by our client from Austria. Here is what he said:

This machine worked well with cow manure. It works smoothly without clogging. Very good product, even better than what I expected. The sales manager is friendly, helpful, and very professional. We will buy it again when we have built another farm.

What Our Clients Say

The manure dewatering machines can meet the need for sustainable manure management systems in Moldova, we used 2 units to process pig waste, which will bring economic benefits to farmers. Although this is the first time for the company to cooperate, it is trustworthy and will continue to order equipment in the future. Thank you, Kerry.

Excellent work and beautiful workmanship! The dewatering machine we received is in great condition. We are very pleased with the quality and performance of the machine. A special thanks to Alan for all his hard work and dedication. We will consider ordering a larger model in the future!

Very satisfied! I ordered the FR-180 machine for the second time and very recommended it. Thank you for being so friendly and for answering all my doubts. This machine has been working well and has solved a big problem for my farm.

How Does A Manure Separator Work?

A screw manure separator uses a screw mechanism to push the liquid through a perforated screen, effectively separating the solids from the liquids. Here's a breakdown of how it works:

1. Feeding: Manure slurry is fed into the separator by a pump or feed hopper.

2. Screw Mechanism: The screw, powered by an electric motor, rotates within a cylindrical housing. As the material is pushed forward by the rotating screw, it moves through the screen.

3. Separation Process: The liquid flows out through the screen. While the screw continually pushes the solids toward the end of the machine where they are compacted and expelled.

4. Solid Discharge: The dewatered solids are discharged at the end of the separator.

The manure separation process is simple and energy-saving. You can also use conveyor belt to improve the automation level of your manure processing line.

Manure Dewatering Machine Videos

End Products of Manure Dewatering

1. Dewatered Solid

- The dewatered manure can be directly used as fertilizer. Or the separated cow dung and chicken manure can be mixed with organic materials such as sawdust or soil for composting and fermentation. However, pig manure is too watery and can only be used after solid-liquid separation.

- The solids are also used as bedding material for livestock.

- Used as feedstock for biogas production.

2. Liquid Effluent

- Can be used to produce biogas through anaerobic digestion.

- Used as a natural liquid fertilizer for crops.

Reliable Manure Dewatering Solution Supplier

As a leading manufacturer of solid-liquid separation equipment, Furui Machinery sells hundreds of manure dewatering machines worldwide each year. Since 2011, we’ve built a strong reputation for quality, reliability, and performance. Long-term partners from Germany, Austria, Spain, Thailand, the Philippines, and many other countries continue to choose Furui Machinery -- because they trust our machines and our service.

Whether you’re dealing with livestock manure, biogas slurry, or wastewater treatment, our dewatering machines will solve your real challenges. Contact us today for a free consultation - let’s find the right manure dewatering system for your needs.

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat