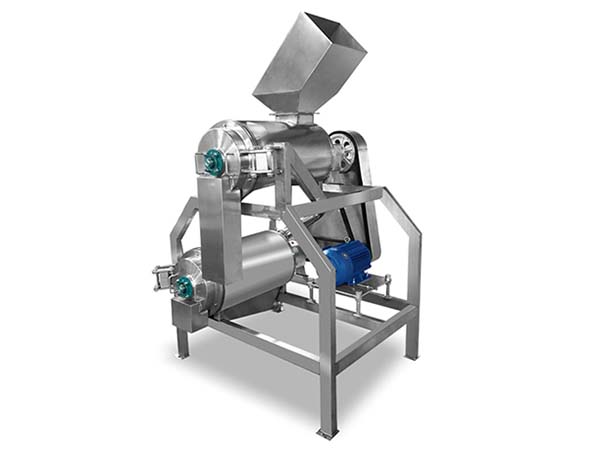

Fruit Pulper Machine

Fruit pulper machine is a versatile piece of equipment engineered for the efficient pulping of fruits and vegetables. It is capable of automatically separating seeds and skin from the fruit pulp, delivering a smooth and consistent output. Furui Machinery offers a range of fruit pulper machines tailored to meet the specific requirements of different materials.

- Capable of processing a variety of materials, like tomatoes, mangoes, kiwis, strawberries, pre-cooked dates, cut peppers, celery, etc.

- Automatic separation of pulp and residue.

- Constructed from high-quality stainless steel, ensuring food safety and ease of cleaning.

- Can be integrated into a production line or used as a standalone unit.

Specifications of Fruit Pulper Machine

Furui Machinery offers different types of fruit pulp machines for sale, including the DJ series and MDJ series.

The DJ series is available in single (DJ1), double (DJ2), or triple-channel (DJ3) models. Please check more parameters from the table on the right.

This series is suitable for pulping materials like pre-crushed tomatoes, kiwis, strawberries, grapes, pre-cooked hawthorn, jujube, chopped greens, peppers, celery, and other vegetables.

| Model | Power | Capacity | Rotating Speed | Machine Size (mm) |

| DJ1-0.12 | 1.5 kW | 0.12 t/h | ≤860 r/min | 820×450×950 |

| DJ1-2.5 | 4 kW | 2.5 t/h | ≤860 r/min | 1450×770×1523 |

| DJ1-3.5 | 5.5 kW | 3.5 t/h | ≤860 r/min | 1550×770×1530 |

| DJ1-5 | 11 kW | 5 t/h | ≤860 r/min | 1750×1000×1700 |

| DJ2-0.24 | 3 kW | 0.24 t/h | ≤860 r/min | 820×1000×1350 |

| DJ2-4 | 7.5 kW | 4 t/h | ≤860 r/min | 1370×1370×1800 |

| DJ2-7.5 | 11 kW | 7.5 t/h | ≤860 r/min | 1935×2275×1700 |

| DJ3-7.5 | 18.5 kW | 7.5 t/h | ≤860 r/min | 1935×2275×1700 |

DJ1 Fruit Pulp Machine

MDJ Mango Pulp Machine

The MDJ series is designed for pulping and core-removing of various fruits to separate pulp, peel, and core. This series is available in single-channel (MDJ1) and double-channel (MDJ2) models. Besides the materials mentioned above, the MDJ series can also core-remove and pulp large-seed fruits such as mangoes, apricots, and plums.

| Model | Power | Capacity | Dimension (mm) |

| MDJ1-2.5 | 5.5 kW | 2.5 t/h | 1,450*770*1,650 |

| MDJ2-4 | 7.5 kW | 4 t/h | 1370*1370*1800 |

| MDJ2-5 | 11 kW | 5 t/h | 1650*1370*2000 |

Features

- Screen: The machine features a cylindrical screen with multiple aperture sizes, which can be customized according to user requirements.

- Variable Speed Control: The pulping speed can be adjusted using a variable frequency drive, allowing for precise control over the process.

- Material: All parts that come into contact with the product, as well as the machine's frame, are constructed from SUS304 stainless steel, ensuring both durability and food safety.

Structure

The machine is composed of several key components, including a feeding hopper, residue outlet, juice outlet, cylinder, screen, pulping blade, frame, and transmission components.

- Double and Triple-Channel Pulper: Each channel in these models shares the same structure as the single-channel pulper.

- MDJ Pulper: Similar to the DJ series, the MDJ pulper is equipped with a core-removal rotor for efficient de-pitting.

Single Channel Pulper Machine

Double Channel Pulper Machine

Working Principle of Fruit Pulper

1. Drive Mechanism: The pulper machine operates with a motor that transmits power via a belt drive.

2. Pulping Process: The crushed fruits are fed into the machine through the feed port. As the rotor rotates, the pulp collecting tray evenly distributes the material onto the scraper blades and the screen. The combined effect of the rotating scraper blades and the lead angle causes the material to move along the cylindrical screen toward the discharge end in a spiral trajectory. As for the double-channel pulping machine, the first stage is coarse pulping and the second stage is fine pulping.

3. Separation: As the material moves between the scraper blades and the screen, centrifugal force causes it to be rubbed and crushed. The juice and pulp pass through the screen and are sent to the next processing stage. The peel and seeds are automatically separated and discharged through the waste outlet.

Choosing Between Industrial Juicer and Fruit Pulper

Some fruits and vegetables can be both juiced and pulped, for example, apples, pears, tomatoes, strawberries, blueberries, sea buckthorn, blackberries, and more.

- If you want juice with minimal pulp, then use a juicer machine; while if you want thicker juice with more pulp, pulper machine is recommended.

- Use a de-pitting pulper machine for fruits with large pits, such as mangos, peaches, cherries, apricots, and plums.

- For fibrous vegetables, such as celery: Use a pulper machine for better efficiency and yield.

- Fruits like apples or pears should be pre-cooked before pulping if you want thicker pulp.

At Furui Machinery, we offer a range of high-quality industrial juicer and fruit pulper machines to meet your specific needs. Whether you want clear juice or thick pulp or puree, we can provide the right machinery. Welcome to contact us for more details!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat