Flat Labeling Machine

Whether you’re labeling books, boxes, bags, or square bottles, the flat labeling machine offers a cutting-edge solution. Designed to apply labels to flat surfaces, this versatile machine is an essential tool for various industries like printing, food, electronics, pharmaceuticals, and more.

- Can be used as a standalone unit or integrated into existing production lines.

- Handles a wide range of product types, including books, cartons, bags, square bottles, bottle caps, and more.

- Available in both semi-automatic and automatic models, and come in floor-standing and tabletop configurations.

Flat Labeling Machine

Flat labeling machine is one of the most innovative solutions designed to handle the diverse labeling needs of various industries. Specifically engineered for applying labels to flat surfaces, a flat labeler is ideal for a wide range of products, including boxes, cartons, bags, bottle caps, square or rectangular bottles, and more. Furui Machinery offers both semi-automatic and automatic flat labeling machines for sale, providing flexible and efficient solutions to suit different production requirements. Besides, these machines can even integrate with printers, and coders, to add dynamic data during the labeling process.

Applications:

- Food and Beverage Industry: Applying labels on the sides or tops of bottles (e.g., bottled water, sauces, and juices), jars (e.g., jam, honey), cans, products packaged in boxes (such as frozen food or snack foods);

- Pharmaceuticals: Label pharmaceutical products, such as medicine boxes, blister packs, pill bottles, vials, boxes, and cartons;

- Cosmetics and Personal Care: For flat packaging for soaps, creams, lotions, shampoos, and other personal care products;

- Logistics and Packaging: For labeling shipping boxes, pallets, crates, large containers, and retail-ready packages;

- Electronics and Consumer Goods: Electronic devices (e.g., mobile phones, tablets, laptops), electronic components (e.g., batteries, circuit boards, chargers).

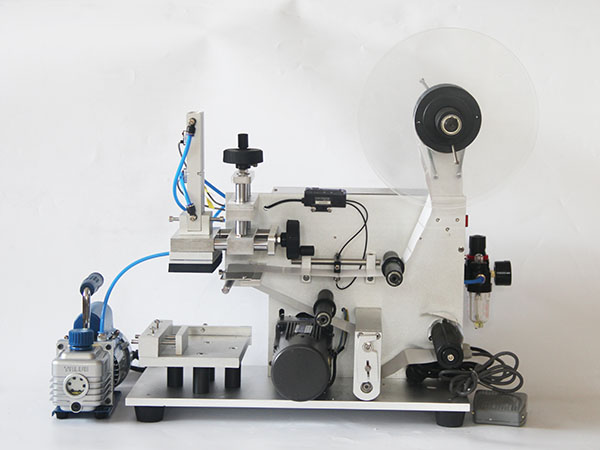

Semi-automatic Flat Labeling Machine

In the semi-automatic models, the operator manually places the product onto the machine, while the label-applying process is fully automated. Furui Machinery offers two models: TB-60 (without a coding machine) and TB-60D (with a coding machine).

- Equipped with an advanced positioning system to ensure accurate and consistent label placement.

- The labeling head uses pneumatic lifting technology, allowing smooth vertical adjustments to suit containers of varying heights.

- Features a customizable positioning clamp board. Operators can adjust the positioning rod based on the actual size of the products.

| Model | TB-60 | TB-60D (with coding machine) |

| Voltage/Power | 110V/220V, 50Hz/60Hz 120W | |

| Labeling Speed | 25-50 pcs/min | 25-40 pcs/min |

| Accuracy | ±1mm | ±1mm |

| Label Size | L30-60*W10-120mm | L30-60*W10-120mm |

| Label Roll Inner Diameter | 75mm | 75mm |

| Label Roll Outer Diameter | 250mm | 250mm |

| Machine Dimensions | 650*450*700mm | 680*450*700mm |

| Weight | 30kg | 40kg |

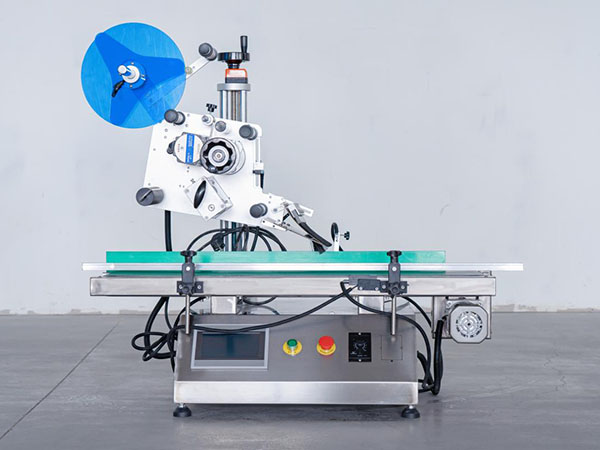

Automatic Flat Labeling Machine

Automatic flat labeling machine is a highly efficient and precise piece of equipment designed to apply labels to the flat surfaces of various products without the need for manual intervention. This makes it an ideal solution for high-volume packaging lines.

- Equipped with advanced sensors, ensuring that labels are accurately applied without missing any, minimizing the risk of labeling errors.

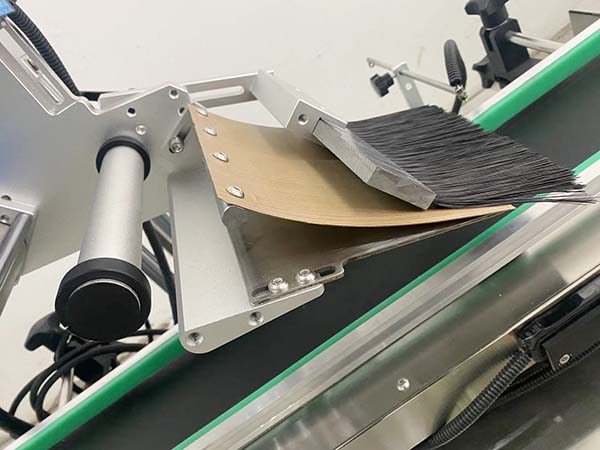

- With high-quality label winding mechanism that guarantees precise, non-slip, and wear-resistant label pulling.

- PLC touch panel allows for easy setup and adjustments, making it simple to configure machine parameters such as label size, and speed, etc.

- Automatic collection tray is designed for easy handling and disposal of used labels or excess material.

| Model | TB-150 | TB-300 |

| Voltage | 220V/110V 50-60Hz | 220V/110V 50-60Hz |

| Label Size | 15-130mm | 25-300mm (L) * 15-200mm (W) |

| Speed | 40-60 pcs/min | 60-300 pcs/min |

| Dimensions | 1,300*850*650mm | 2,000*550*1,600mm |

| Machine Weight | 100kg | 180kg |

| Label Roll Inner Diameter | Φ76mm | Φ76mm |

| Label Roll Outer Diameter | Φ300mm | Φ300mm |

Desktop Flat Labeling Machine

Flat Labeler

Double-side Labeling Machine

Double side labeller is a versatile and highly efficient solution designed to apply labels to both sides of various products simultaneously. It is specifically engineered for products such as flat bottles, round bottles, square bottles, and irregular-shaped containers. It can label both single and double sides of bottles in one pass, increasing production efficiency.

- Automatic Alignment: Equipped with a rigid plastic synchronizing guiding chain, the machine ensures that bottles are perfectly aligned.

- Automatic Spacing: An automatic bottle separation system ensures the correct spacing between bottles for consistent labeling.

- Double Labeling Mechanism: The machine is equipped with a double labeling system. The first pass ensures label placement accuracy, while the second pass applies a compression function to remove air bubbles and ensure that the label adheres securely.

- Constructed from high-quality stainless steel and aluminum alloys, the machine meets GMP standards, offering both durability and aesthetic design.

| Model | TB-160 |

| Voltage | 220V/110V 50-60Hz |

| Labeling Speed | 60-300 pcs/minute |

| Labeling Precision | ±1.0mm |

| Applicable Product Size | 30-350mm 20-120mm |

| Label Size | 25-300mm (L) * 15-200mm (W) |

| Label Roll Inner Diameter | Φ76mm |

| Label Roll Outer Diameter | Φ300mm |

| Weight | 450kg |

| Dimensions | 2,800*1,650*1,500mm |

Reasons to Trust Furui Machinery

Flat labeling machines are essential for applying labels to products with flat surfaces, such as cartons, boxes, or flat bottles. When choosing the right labeling machine, several factors must be considered to ensure optimal performance and productivity. Here’s why Furui Machinery stands out as your preferred supplier:

-

Product Compatibility: Our flat labeling machines are designed to accommodate various product sizes and shapes. Our machine is also capable of labeling products with diverse surface materials, including cardboard, plastic, glass, and metal. This flexibility guarantees that our machines meet the needs of different industries.

-

Labeling Accuracy: Equipped with advanced sensors, our machines automatically detect product presence, ensuring that labels are applied precisely in the correct position every time. This minimizes the risk of errors, providing high-quality labeling results.

-

Multi-Product Handling: One of the key advantages of Furui’s flat labeling machines is their easy adjustability. They are designed to handle a wide range of label sizes, shapes, and material types, making it simple to switch between different products without extensive downtime.

-

After-Sales Support: At Furui Machinery, we believe in building long-term partnerships with our clients. We offer comprehensive after-sales support, including technical assistance and access to spare parts.

-

Seamless Integration: Add coders, printers, or RFID systems effortlessly.

-

By choosing Furui Machinery, you’re investing in reliable and adaptable labeling machines backed by exceptional customer support. We supply various packaging equipment and solutions to meet your needs. Welcome to contact us for more details!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat