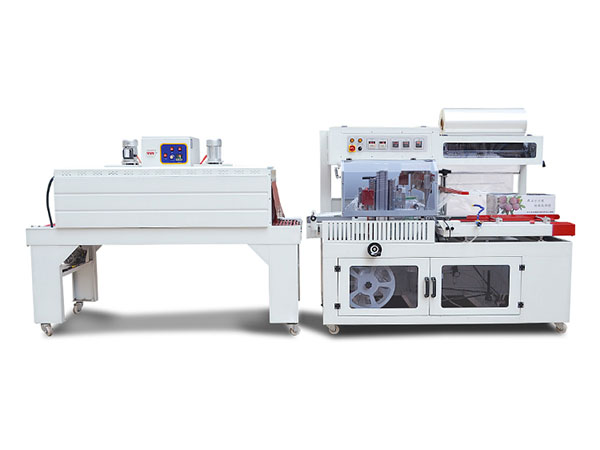

Automatic Shrink Wrapping Machine

Automatic shrink wrapping machine is a packaging system that combines an automatic sealing machine and a heat shrink tunnel. It works by automatically wrapping products in shrink film, sealing it, and then applying heat to shrink the film tightly around the product, creating a protective and aesthetic layer. This machine is designed for high-volume and continuous operation, delivering fast and efficient packaging solutions.

- Suitable for packaging cans, bottles, trays, boxes, cartons, books, etc;

- Equipped with different sealing machines according to your needs.

Automated Shrink Wrap Machines

Automatic shrink wrapping machine is designed to efficiently wrap products in shrink film, providing secure, smooth, and visually appealing packaging. This advanced machine streamlines the packaging process by automatically feeding, wrapping, sealing, cutting, collecting waste film, and shrinking. Ideal for high-volume packaging needs, it is well-suited for industries such as pharmaceuticals, food and beverage, cosmetics, electronics, and toys, where speed, consistency, and quality are essential.

Furui Machinery has specialized in providing a variety of heat shrink packaging machines for over 20 years, offering a comprehensive selection of industrial shrink wrap systems to meet diverse needs. Welcome to contact us for more details today!

Key Components

1. Automatic Sealing Machine:

This machine is responsible for wrapping products with shrink film and sealing them with heat. At Furui Machinery, various sealing machines are available, including side sealer, sleeve sealer, and L bar heat sealer.

2. Shrink Tunnel:

Its primary function is to apply heat to the wrapped products, causing the film to shrink tightly around the product. We offer different types of heat shrink tunnel machines to choose from, including the BS series (suitable for PVC and POF film) and the BSE series (designed for PE shrink).

Our auto shrink wrapping systems include L-bar sealer with shrink tunnel, side-sealer with heat shrink tunnel, and sleeve sealer with shrink tunnel.

L-Bar Sealer with Shrink Tunnel

L-bar sealer forms an "L" shape seal around the product, cutting and sealing the shrink film in one step.

This system uses a conveyor belt to deliver the product into place, then the L-shaped sealer is triggered to form a tight wrap around the product. Then the wrapped product moves to a shrink tunnel where heat is applied, causing the film to shrink tightly around the product. This versatile system is ideal for small items and is perfect for businesses with low to medium production volumes.

- The L-bar sealer uses two sealing blades arranged in an “L” shape.

- We have three models of L-bar heat sealers for sale, which can package 15-30 items per minute.

- Suitable film: PE and POF

Side Sealer With Shrink Tunnel

This automatic shrink wrapper is particularly used for wrapping products of varying lengths, such as boxes, books, or trays.

- Sealing blades of the side sealer are separated. This design allows the machine to package products of different widths and heights, especially for wrapping long products like curtain rods, and more.

- Side sealers can create a continuous seal along one side of the film as the product moves through, making it faster for high-volume packaging.

- Seal and shrink up to 35 items per minute.

- Can be integrated with automated packaging lines.

Sleeve Wrapping Machine

The sleeve wrapper applies a band of shrink film around the product, leaving the ends open.

- Widely used in the production lines of beverages, beer, mineral water, and more;

- Easy to adjust the settings to suit a wide range of packaging sizes and adaptable to different product dimensions and packaging quantities;

- Efficient for bundling multiple items together, such as trays, cans, or bottles;

- Widely used for larger and heavier products like wood, steel, and ceramics.

How Does Automatic Shrink Wrap Machine Work?

1. Product Feeding

Products are automatically fed into the machine via a conveyor system, streamlining the packaging process.

2. Wrapping and Sealing

As the product moves along the conveyor, shrink film is wrapped around it in the designated wrapping area. After wrapping, the film is sealed and cut to form a secure package.

3. Shrinking

After sealing, the product is transported through the shrink tunnel, where heat is applied evenly to the film. This process causes the film to contract tightly around the product, resulting in a secure, professional, and smooth finish.

Features of Automatic Shrink Wrap Machine

1. High Automation Level

Our automatic shrink wrap systems are highly automated, such as automatic feeding, film wrapping, sealing, and waste film collection. This significantly reduces labor costs and also improves overall efficiency.

2. High Packaging Speed

The packaging speed of our shrink wrap machines can reach up to 35 packs per minute. This makes them ideal for businesses that require fast and efficient packaging solutions for high-volume production.

3. Great Durability

The sealing knife is coated with Teflon, providing excellent non-stick and high-temperature resistance. The sealing frame is made from high-quality alloy steel, which is resistant to deformation even during prolonged use.

4. Wide Applications

These machines can package a wide range of products, from food and beverages to industrial goods. Besides, is easy to adjust the settings to make them suitable for packaging items of various sizes and shapes.

5. Customization Options

Our automatic shrink wrapper can be customized with adjustable speeds and temperature based on your specific needs. In addition, the machine can accommodate products of various sizes without requiring mold changes.

6. Film Compatibility

Our shrink wrappers support a variety of films, including PE, POF, and PVC. This versatility makes it easy to select the appropriate film based on their packaging needs.

Conclusion

Automatic shrink wrapping machine offers a fast and reliable packaging solution. At Furui Machinery, we offer different types of automatic shrink-wrapping systems to choose from. Whether you are food products, electronics, pharmaceuticals, or industrial parts, or bundle products together, contact Furui Machinery and we will provide you with a suitable wrapping system to meet your specific needs.

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat