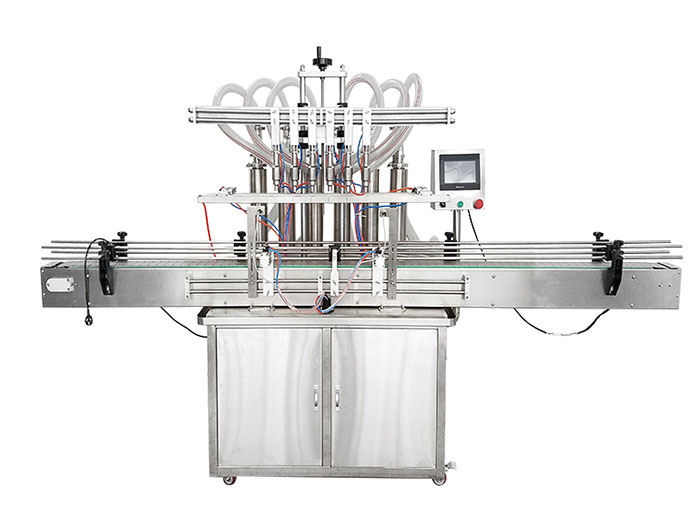

Automatic Liquid Filling Machine

Automatic liquid filling machine is ideal for filling diverse products such as liquids, pastes, and sauces. It is widely used across industries such as chemicals, food, oil, pharmaceuticals, and more. Furui Machinery offers both linear filling machines and servo filling machines to meet various production needs.

- Available in configurations with 2, 4, 6, or 8 filling heads for flexibility;

- PLC control system for accurate and consistent filling;

- User-friendly touchscreen interface for easy adjustments;

- Contact parts are made from stainless steel for hygiene and durability.

Automatic Liquid Filling Machine

An automatic liquid filling machine is a type of machinery designed to fill containers, such as bottles or jars, with liquid products in a fully automated process. These machines are commonly used in various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals.

Furui Machinery offers two series of automated filling machines: inline liquid filling equipment and servo liquid filling machines. These versatile machines can operate as standalone units or seamlessly integrate with other equipment, such as capping machines and labeling machines, to streamline your production line.

Inline Filling Machine

Our inline filling machine is a type of automated equipment used for filling products into containers such as bottles, jars, or cans. This versatile equipment is widely employed across various industries, making it ideal for filling liquids like juice, vinegar, and liquor, as well as pastes, creams, sauces, jam, edible oil, lotions, laundry detergent, and more.

- Linear Bottle Handling: The machine uses a linear grouping method for the entry and exit of bottles, ensuring effective filling for various container shapes.

- User-Friendly Controls: The PLC system, paired with a touchscreen interface, allows for easy adjustments, enhancing overall performance.

- Customizable Filling Options: With adjustable filling volume and speed, the machine can be tailored to meet specific production requirements.

| Item | Paste Filling | Liquid Filling |

| Power | 500W | |

| Voltage | 220V/110V 50/60Hz | |

| Air Pressure | 0.5-0.7Mpa | 0.4-0.6Mpa |

| Filling Speed | 5-60 bottles/min | |

| Accuracy | ±1% | |

| Filling Range | 10-100 ml, 30-300 ml, 50-500ml | |

| Filling Heads | 2, 4, 6, 8 (can be customized) | |

Inline Paste Filling Machine

6-head Inline Liquid Filling Machine

Nozzle

Applications:

- Beverage Industry: Used for filling liquids like water, juice, milk, and soft drinks into bottles or containers.

- Cosmetics and Personal Care: Filling lotions, creams, shampoos, and gels into bottles or jars.

- Pharmaceuticals: For filling medicines, syrups, and other health-related liquids or creams.

- Food Processing: Used to fill sauces, paste, oils, jams, or honey into containers.

- Chemical Industry: Filling hazardous chemicals, detergents, or other liquid chemicals into appropriate containers.

Servo Filling Machine

A servo liquid filling machine uses servo motor technology to control the filling process, ensuring high precision and consistency. It is an ideal choice for filling liquid and paste products, especially for high-viscosity materials, such as laundry detergent, hand soap, lubricant, chili sauce, ketchup, nut butter, sticky honey, syrup, coating, and more.

- Precision Filling: The servo motor drives the piston, ensuring accurate and consistent filling volumes.

- Adjustable Filling Volume: The filling amount can be easily adjusted via a user-friendly LCD touchscreen interface, enhancing convenience.

- Versatility: Suitable for filling a wide range of materials, including liquids, semi-fluids, and viscous liquids.

| Item | Automatic Servo Filling Machine |

| Filling Speed | 0-100 bottles/min |

| Power | 1000 W |

| Voltage | 220V |

| Air Pressure | 0.5-0.7Mpa |

| Filling Capacity | 90-520ml |

| Filling Heads | 2,4,6,8 (can be customized) |

| Filling Range | 50-500ml, 100-1000ml, 500-3000ml, 1000-5000ml |

Servo Filling Machine

Paste Filling Machine

Working Principle of Automatic Liquid Filling Machine

1. Container Conveyance

Before filling begins, empty containers are transported from the conveyor belt to the filling area.

2. Filling Volume Setting

Operators can set the desired filling volume on control panel. This allows for easy adjustment to your requirements.

3. Liquid /Paste Supply

Once the filling volume is set, the liquid or paste is delivered from a storage tank to the machine's work platform through a piping system.

4. Quantitative Filling

When the liquid or paste reaches the work platform, the machine accurately fills each container according to the preset volume using valves or pump systems.

Advantages of Automatic Filling Machines

High Efficiency

The automated operation significantly speeds up the entire filling process, maximizing productivity.

Automation

Inline machines are designed for automated, high-speed operation with minimal downtime, Features such as anti-drip nozzles help prevent contamination, ensuring a clean and hygienic filling process.

Precision Filling

Our inline fillers are equipped with advanced sensors and control systems to ensure precise, consistent filling volumes, reducing the chances of overfilling or underfilling.

Hygiene and Durability

Constructed from stainless steel, these machines are durable to use, easy to clean and maintain, ensuring product safety throughout the filling process.

Integration with Production Lines

These machines can be easily integrated into production lines, such as sealing and capping, facilitating a seamless workflow.

Flexibility

Our automatic liquid filling machines are easily adjusted for different container sizes, accommodating various packaging needs.

Conclusion

Furui Machinery is a trusted supplier of filling and packaging solutions, offering both semi-automatic and fully automatic filling equipment tailored for various industries, including food, pharmaceuticals, and daily chemicals. In addition, we provide related equipment such as capping machines, sealing machines, and heat shrink tunnels. Welcome to contact us for more information!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat