Delivering Dewatering Screw Press to Malaysia

11/13/2024

Delivery of Inclined Screen Separators to Philippines

12/23/2024

Delivering Dewatering Screw Press to Malaysia

11/13/2024

Delivery of Inclined Screen Separators to Philippines

12/23/2024Labeling machines play a crucial role in the manufacturing and packaging processes across various industries. The right labeling machine ensures efficiency, consistency, and quality, tailored to specific needs based on the material, shape, speed, and type of label required. In this post, we'll explore the most common types of labeling machines and how they are classified. In this guide, we’ll break down the most common types of labeling machines and their classifications to help you select the best fit for your packaging needs.

Types of Labeling Machine

Labeling machines can be classified based on several factors: label material, automation level, machine design, product shape, and packaging type. Let's take a closer look at each category.

1. By Label Material

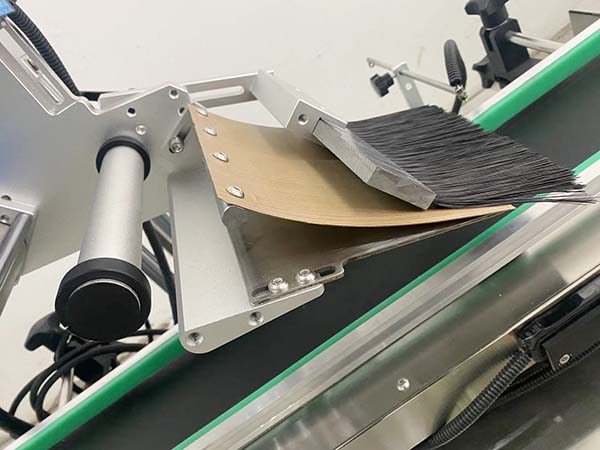

1.1. Pressure-Sensitive Labeling Machine

Pressure-sensitive labeling machine is one of the most widely used types of labeling equipment across various industries. This machine is designed to apply self-adhesive labels to products without the need for heat, water, or solvents. The labels are pre-coated with adhesive on the back, allowing them to bond directly to the product's surface when pressure is applied. As the label roll moves, the peel plate separates the label from its backing material. Once the label is separated, it is transferred to the applicator, which then uses controlled pressure to position the label precisely and evenly on the product, providing a clean, professional finish.

Label Material: Self-adhesive pressure-sensitive labels.

Product Compatibility: Capable of labeling various bottle shapes, including square, rectangular, and round bottles.

1.2. Hot Melt Labeling Machines

Hot melt labeling machines use molten glue to apply labels. The glue is melted at temperatures between 160°C and 180°C and then applied to the label or product. As the hot melt adhesive cools, it quickly solidifies, forming a secure, long-lasting bond between the label and the container.

Label Material: Suitable for OPP film, paper-plastic composite, and paper labels, with the adhesive applied as a hot melt.

Localized Glue Application: Minimizes glue consumption and waste.

1.3. Shrink Sleeve Labeling Machine

A shrink sleeve labeling machine applies a label made from a shrinkable plastic material (such as PVC, PET, or OPS) to a product. The label is applied as a loose sleeve around the container, and heat is used to shrink the label so that it tightly conforms to the shape of the product.

Label Material: Shrink sleeve labels, made of materials like PVC, PET, or OPS.

Tamper-Evident: The shrink label can act as a tamper-evident seal, providing a visual indicator that the product has not been opened.

Product Compatibility: Ideal for labeling bottles, cans, and irregularly shaped containers.

Auto Bottle Labeling Machine

Labeling Feeding System

2. By Automation Level

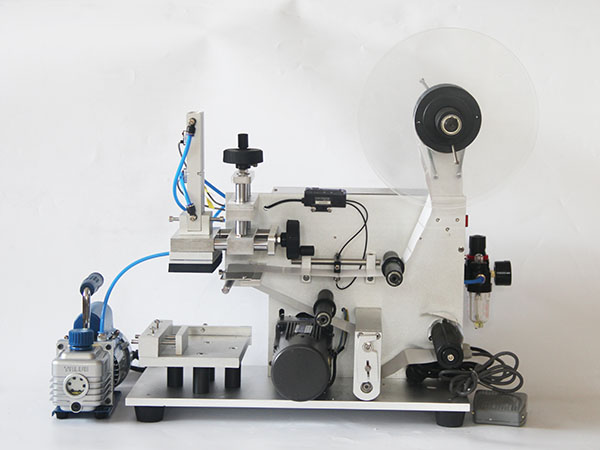

2.1. Semi-Automatic Labeling Machine

Semi-automatic labeling machines require some manual operation but automate the labeling process once the product is positioned. In these machines, the operator manually places the product onto the conveyor system or positioning tray. Once the product is correctly placed, the machine automatically applies the label.

2.2. Automatic Labeling Machines

Automated labeling machines require no manual labor for product handling. Using sensors and conveyors that detect, position, and apply labels to products without manual intervention. These machines are ideal for high-volume production lines and can be integrated with other systems, such as capping, filling, or coding equipment.

2.3. Manual Labeling Machines

Manual labeling machines are the simplest and most cost-effective option, often used in small-scale operations or for businesses just starting. These machines require the operator to manually apply labels to the product.

Semi-auto Labeling Machine

Table-top Automatic Labeling Machine

3. By Product Shape and Packaging Type

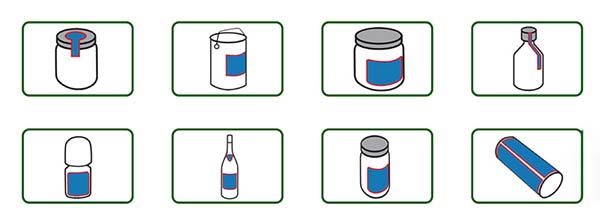

3.1. Round Bottle Labeling Machines

Round bottle labeling machines are designed specifically to label cylindrical products such as bottles, jars, cans, and other round containers.

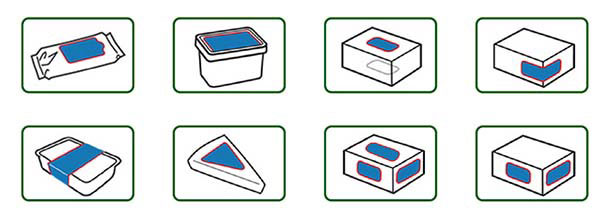

3.2. Flat Surface Labeling Machines

Flat surface labeling machines are designed to apply labels to flat surfaces, such as boxes, cartons, bottle tops, and rectangular, or square bottles.

3.3 Irregular Shape Labeling Machines

These machines are designed to adapt to the unique contours of non-standard or irregularly shaped containers such as oval bottles, jars with unusual shapes, and other asymmetrical packaging.

3.4. Double-Side Labeling Machine

Double side labeler is designed to apply labels on both the front and back sides or two tops of a product simultaneously.

3.5. Wrap-Around Labeling Machine

A wrap-around labeling machine is designed for applying labels that wrap completely around cylindrical or bottle-shaped products.

3.6. Corner Wrap Labeling Machine

A corner wrap label applicator is designed for products that require a label to be applied at the corner of a package or product. This type of labeling machine is ideal for boxes, cartons, and other packaging where labels need to wrap around the corners, providing both branding and tamper-evident features.

4. By Design

4.1. Rotary Labeling Machine

Rotary labeling machines use a rotating system to apply labels to products. These machines are ideal for high-speed production lines, where large volumes of products need to be labeled quickly and efficiently.

4.2. Inline Labeling Machine

Inline labeling machines operate in a straight line, with products moving through the labeling process along a conveyor.

4.3. Floor-Standing Labeling Machine

Floor-standing labeling machines are larger, industrial-grade systems designed to be placed on the floor of the production facility.

4.4. Tabletop Labeling Machine

Compact and versatile, tabletop labeling machines are designed for smaller operations or businesses with lower production volumes. They’re easy to set up and move, making them ideal for flexible use in small spaces.

Floor-standing Labeling Machine

Flat Labeling Machine

Conclusion

Labeling machines come in a wide variety of configurations, making it easier than ever to find the right solution for your specific needs. Whether you're labeling a round bottle, a flat box, or irregularly shaped products, there is a labeling machine that can suit your needs. From manual to fully automatic machines, each type is designed to cater to specific product requirements, production volumes, and label types. Understanding the types and classifications will help you make an informed decision on the most suitable labeling machine for your operation. If you have any questions or need a quote, don’t hesitate to contact us. We're here to help!