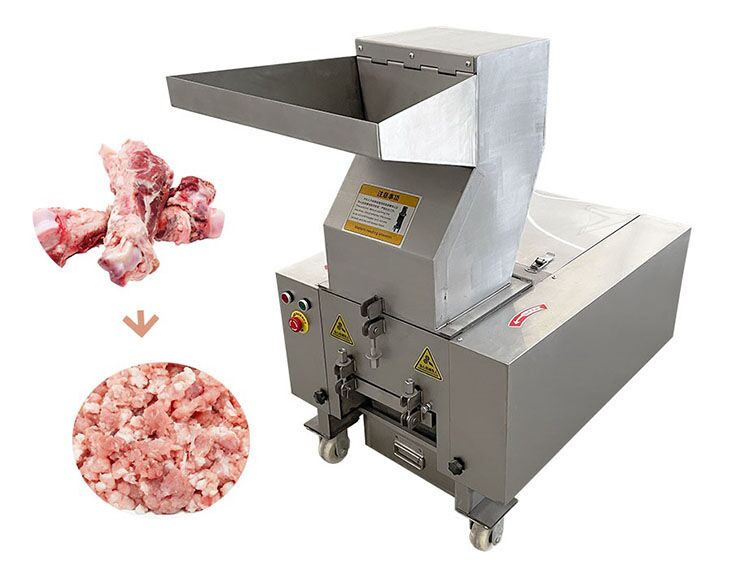

Bone Crusher Machine

A bone crusher machine is an industrial device designed to crush and grind animal bones into small pieces. It is versatile and capable of processing a wide range of frozen or fresh bones, including those from cows, pigs, sheep, donkeys, chickens, and even whole fish.

- Allows for adjustable size of crushed bones, ranging from 5mm to 50mm;

- Constructed from high-quality 304 stainless steel, ensuring durability, hygiene, and long-lasting use;

- Can be integrated with conveyors for automated feeding and discharge;

- Crushed bones can be ground into a fine paste using a bone grinder.

Bone Crusher Machine for Sale

Bone crusher machine can effectively crush large bones and other hard materials into small pieces ranging from 5mm-50mm. It is commonly used as a coarse crushing process in production lines. When paired with a bone grinder, it becomes an essential tool in producing various food products, such as sausages, ham, luncheon meat, bone powder, bone broth, and pet food. Furui Machinery offers a wide range of bone crusher machines for sale. Below are more parameters for your reference.

Bone Crushing Machine for Sale

Stainless Steel Bone Crusher

| Model | PG-180 | PG-230 | PG-300 | PG-400 | PG-500 | PG-600 | PG-800 | PG-1000 |

| Voltage | 380V/220V | 380V/220V | 380V | 380V | 380V | 380V | 380V | 380V |

| Power | 3 kW | 4 kW | 5.5 kW | 7.5 kW | 11 kW | 15 kW | 30 kW | 37 kW |

| Capacity (kg/h) | 20-60 | 30-100 | 80-250 | 200-400 | 350-600 | 500-900 | 750-2,000 | 1,000-4,000 |

| Dimension (mm) | 700*600*900 | 970*610*910 | 1,150*730*1,150 | 1,150*830*1,150 | 1,350*950*1,300 | 1,350*1,050*1,300 | 1,550*1,300*1,550 | 1,800*1,600*1,800 |

| Rotary Speed | 650 r/min | 650 r/min | 780 r/min | 780 r/min | 820 r/min | 820 r/min | 850 r/min | 850 r/min |

| Weight | 180 kg | 240 kg | 350 kg | 400 kg | 580 kg | 650 kg | 1,500 kg | 2,500 kg |

Blades

Meat Bone Crusher

Bone Crushers

What Are Crushed Bones Used for?

Crushed bones have a wide range of uses across various industries, including:

- Food Processing: Crushed bones are often processed into bone paste or powder, which is widely used in products like sausages, ham, meatballs, bone broth, seasonings, and more.

-

Pet Food or Animal Feed Manufacturing: One of the largest uses of crushed bones is in pet food production. Bone meal, rich in essential nutrients such as calcium and phosphorus, is a valuable supplement in livestock, poultry, and pet feeds.

- Gelatin and Collagen Production: Crushed bones are a key raw material for gelatin and collagen, used in food items like jellies, and gummy candies.

-

Pharmaceuticals: Crushed bones are used to produce calcium supplements and bone-derived medicinal products. The machines ensure that bones are processed to the fine powder required for pharmaceutical use.

How Does A Bone Crusher Machine Work?

The working process of the bone crusher is based on a shearing and crushing mechanism. Here's how it operates:

1. Feeding: Bones are loaded into the machine’s large, inclined feed hopper. The design ensures fast and efficient feeding, preventing blockages.

2. Crushing: Inside the machine, rotating teeth made from high-quality alloy steel shear and push the bones towards the pre-cutting knife plate. As the bones come into contact with the rotating blades and the hole plates, they are crushed into smaller pieces.

3. Discharge: The crushed bone fragments are then pushed through the perforated screen by rotating teeth and discharged into a collection hopper.

Key Features of Bone Crushing Machine

-

Durable Construction: Typically made from stainless steel or carbon steel, these machines are highly resistant to wear and built to last.

- Adjustable Settings: The screen opening sizes and the feeding port size can be customized to meet your specific material requirements, allowing for various material shapes, sizes, and desired particle sizes.

- Easy to Clean and Maintain: Press down the fixed handle of the hopper, and the hopper can be flipped up to open, which is convenient for maintenance and cleaning of the machine.

- Safety Mechanisms: Equipped with safety features such as overload protection, the machines are designed to prevent accidents during operation.

- Integrated in Production Line: The machine can be integrated with a conveyor belt for automatic feeding and discharging, reducing labor costs. It can also be paired with a bone grinder to produce bone paste or mud.

Bone Grinder Machine

A bone grinder machine is designed to grind crushed animal bones or meat into a fine paste. The bone paste is popular in producing bone-based products such as bone broth, pet food, or nutritional supplements. It typically works in conjunction with a bone crusher machine, which breaks large bones into smaller pieces. Here's how the process works:

- Bone Crusher Machine: This machine is used to crush large animal bones into smaller, manageable pieces. It serves as the first step in the bone processing chain, preparing the bones for further grinding.

- Bone Grinder Machine: After the bones are crushed, the bone grinder finely grinds the smaller pieces into a smooth, uniform paste. Using a colloid mill mechanism, this machine ensures the desired consistency and is typically used as the second stage after crushing. If you want uniform meat mince or particles, we also have meat mince machine to choose from.

Applications

Animal Bones, Skins, Meat: The bone grinder machine is versatile to process a variety of materials, such as chicken and duck bones, bones from pigs, cattle, sheep, pig skin and chicken skin, fish and meat, etc.

Fruits and Vegetables: In addition to bone processing, the bone grinder is also used in grinding materials like chili peppers, ginger, garlic, onions, tomatoes, and other fruits and vegetables.

Grains and Nuts: It is also capable of grinding grains and nuts into butter, including sesame, peanuts, walnuts, cashews, pecans, and more.

Bone Grinders

Colloidal Mill

Furui Machinery offers high-quality bone crusher machines and bone grinder machines designed for efficient bone processing. Whether you need to crush large animal bones or grind them into a fine paste, Furui Machinery provides reliable equipment to meet your production needs. Contact us for more information or to request a quote!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat