Commercial Peanut Butter Machine

Commercial peanut butter machine is designed for producing smooth and creamy peanut butter on a large scale. Furui Machinery offers a range of models, with capacities from 10 to 3,000 kg/h, to accommodate diverse production needs.

- One machine, many nuts. Works for almonds, cashews, sesame seeds, pistachios, pecans, cocoa nibs, and more.

- Fits your scale and space. Models for home or small shops up to industrial plants; vertical or horizontal layout, fixed or mobile.

- Can be supplied as a standalone unit or integrated into a complete peanut butter production line.

Peanut Butter Machine for Sale

Furui Machinery offers high-quality and efficient commercial peanut butter machines, suitable for small, medium, and large-scale production with capacities ranging from 10 kg/h to 3,000 kg/h. Featured in advanced colloid mechanisms, these machines ensure efficient dispersion, emulsification, and homogenization.

Our peanut butter mills achieve a particle fineness of 50-200 mesh (adjustable) and a homogeneity rate exceeding 92%, producing smooth, consistent nut butter. Beyond peanuts, these machines are capable of processing a variety of nuts and seeds, including almonds, sesame seeds, cocoa nibs, cashews, and more.

Constructed from stainless steel, our peanut butter making machines are durable, easy to clean, and compliant with food safety standards. Ideal for food processing plants and factories, Furui Machinery's industrial peanut butter machines are a perfect choice for high-volume nut butter production. Check the following table for more details!

Available Models --- Find Your Perfect Match

| Model | JMS-80 | JMS-110 | JMS-130 | JMS-160 | JMS-180 | JMS-210 | JMS-240 | JMS-300 |

| Capacity (kg/h) | 60-80 | 100-200 | 300-500 | 500-600 | 700-800 | 1,000-1,200 | 1,200-1,500 | 3,000-4,000 |

| Power (kW) | 4 | 7.5 | 11 | 15 | 18.5 | 30 | 45 | 75 |

| Voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Weight (kg) | 150 | 175 | 285 | 300 | 375 | 700 | 920 | 1,300 |

| Dimension (mm) | 600*410*930 | 700*430*1,000 | 990*440*1,000 | 1,000*460*1,050 | 1,000*490*1,100 | 1,260*600*1,230 | 1,330*630*1,280 | 1,440*680*1,420 |

| Hopper Capacity | 8L | 8L | 14L | 14L | 14L | 24L | 24L | 32L |

| Rotor Diameter | 80 mm | 110 mm | 130 mm | 160 mm | 180 mm | 210 mm | 240 mm | 300 mm |

| Rotary Speed | 2,890 r/min | 2,900 r/min | 2,930 r/min | 2,930 r/min | 2,930 r/min | 2,950 r/min | 2,970 r/min | 2,970 r/min |

- The voltage can be customized to meet your local requirements.

- Choose between a vertical or horizontal design to suit your space and processing needs.

- The machine can be configured as either a fixed unit or a movable unit based on your preferences.

- The fineness is adjustable by modifying the gap between the rotor and stator.

- Features a circulating cooling water system to dissipate heat generated during grinding.

Stator and Rotor for Peanuts

CE-certified Colloid Mill

Shipping to Canada

Shipping to Vietnam

To South Korea

To Germany

Affordable Peanut Butter Making Machine Price

At Furui Machinery, our peanut butter making machine price starts from $900. Designed to meet diverse production needs, our machines are available in capacities ranging from 30 kg/h to over 3,000 kg/h. Generally, larger capacity machines have a higher cost, but they are ideal for large-scale production.

What’s Included in the Price?

When you purchase a peanut butter grinder from us, you get more than just the equipment:

- Quality equipment, including main body (colloid grinder), motor, stator and rotor (additional stator and rotor available upon request).

- 1-Year Warranty: Enjoy peace of mind with a warranty on the whole machine.

- After-Sales Support: Guidance on machine installation, technical assistance, and spare parts.

- Custom Solutions: Tailored configurations to meet your production needs.

Peanut Butter Machine Videos

Equipment Needed for Peanut Butter Business

- Peanut Butter Grinder: This is the core equipment for grinding peanuts into a smooth butter.

- Peanut Roaster: This machine prepares raw peanuts for grinding by roasting them evenly, enhancing their flavor and aroma. For small-scale businesses, manual roasting can be an economical alternative to reduce costs.

- Peanut Peeling Machine – Removes the red skin of peanuts for a smooth texture.

- Homogenizer – Further refines the texture and prevents oil separation.

- Storage Tank: Storage tanks are used to temporarily hold the peanut paste before packaging. They are also essential for mixing the butter with additional ingredients like sugar, salt, oils, or flavoring agents, ensuring uniform taste and texture.

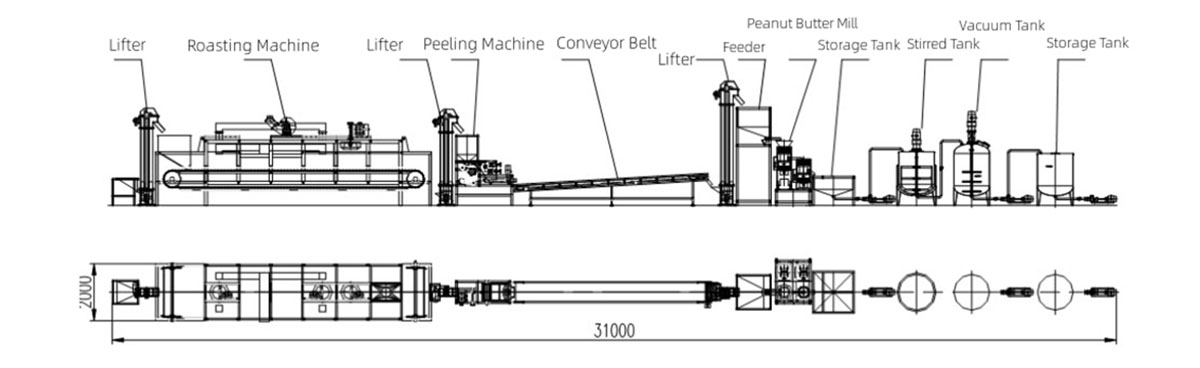

For large-scale peanut butter production, we provide advanced equipment to streamline the process, making it fully continuous and automatic. Our offerings include conveyor belts, lifters, cooling belts, peeling machines, and more. Additionally, Furui Machinery supplies related filling and packaging equipment to ensure a complete and efficient production line.

Automatic Peanut Butter Production Line

Features of Commercial Peanut Butter Machine

Customizable Voltage

The voltage of our machines can be customized according to your requirements. For instance, we offer a single-phase option with a voltage of 220V or a three-phase option with a voltage of 380V to suit different power requirements. Our smaller models, the JMS-50 and JMS-80 are ideal for home uses or small businesses, which can use 220V single phrase. For industrial or commercial applications, a three-phase colloid mill with a voltage of 380V is typically used.

You can select the appropriate equipment based on your specific production needs and the materials you are processing.

Integrated Production Line

Furui Machinery offers a standalone colloid mill specifically designed for peanut butter production. This machine adheres to industry standards for food safety and holds CE certification, ensuring reliable and safe operation.

In addition to the peanut butter grinder, we provide a complete solution for the entire peanut butter production process. Our integrated system includes equipment for peeling, roasting, grinding, and filling, facilitating a seamless production line from raw peanuts to finished products.

Stators and Rotors

The stator and rotor are essential components of a colloid mill. The rotor, which rotates at high speeds, generates the shear forces necessary for processing materials. The stator, positioned very close to the rotor, remains stationary and creates a narrow gap where the material is finely processed.

At Furui Machinery, stators and rotors are available in different materials, structures, and tooth types to meet different material needs. Our peanut butter machine features a grinding head made of 2Cr13 stainless steel, which has undergone a quenching process to achieve high hardness and excellent corrosion resistance. Additionally, the gap between the rotor and stator is adjustable to control the fineness of the peanut butter.

Stainless Steel Construction

Our peanut butter machines are crafted from high-grade stainless steel (SS304 or SS316), ensuring exceptional corrosion resistance, durability, and food safety. The stainless steel material also makes it easy to clean and maintain.

In addition, our machines are certified to meet CE standards, guaranteeing compliance with international quality, and performance regulations.

Frequently Asked Questions

Operating Tips

To ensure optimal performance and longevity of your peanut butter machine, it is essential to follow proper operating tips. Here are some key guidelines for using and maintaining the machine:

1. Pre-Operation Checks:

Before starting production, inspect the machine’s wiring, circuit, and switches to ensure they are in proper working condition.

2. Avoid Foreign Materials:

Ensure that no sharp or hard objects, such as quartz, broken glass, metal chips, or other debris, enter the machine. If any foreign materials are detected, stop the machine immediately.

3. Cleaning

Thoroughly clean the machine after each use to prevent material residue from causing leakage or mechanical issues.

4. Grinding

The materials can be ground once or multiple times depending on their characteristics and the desired processing fineness.

Conclusion

If you're looking to enter the profitable peanut butter industry, a commercial peanut butter machine is the perfect solution. At Furui Machinery, we specialize in high-performance peanut butter machines tailored to meet a wide range of production needs, from small-scale operations to large factories. Our machine features advanced colloid grinding technology, delivering smooth and creamy peanut butter.

Beyond peanuts, this versatile machine can process a variety of nuts and seeds, including almonds, sesame, cashews, hazelnuts, and cocoa nibs, making them ideal for producing other nut butter as well. Moreover, we offer customized configurations, covering every stage from roasting to filling, to perfectly align with your production and packaging requirements. Contact us today for more details!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat