Industrial Orange Juicer Machine

Industrial orange juicer machine from Furui Machinery features a heavy-duty roller press design, ideal for extracting juice from whole citrus fruits like oranges and lemons without peeling. Built with food-grade stainless steel, this high-capacity juicer is perfect for juice factories and commercial uses.

- Whole Fruit Juicing: No need to peel or sort fruits by size (10–110 mm diameter).

- Ideal for Various Citrus Fruits – Suitable for oranges, lemons, tangerines, grapefruits, tangerines, and passion fruit.

- Stainless Steel Construction: Food-contact parts are made of 304 stainless steel, ensuring hygiene and corrosion resistance.

Industrial Orange Juicer for Sale

Our industrial orange juicer is a high-capacity, stainless steel roller press machine designed for commercial juice production. It can extract juice from whole citrus fruits - such as oranges, lemons, limes, tangerines, and more - without peeling or grading.

Furui Machinery offers four models of industrial orange juicers, with processing capacities ranging from 0.5 to 4 tons per hour, making them suitable for juice factories of various scales. Please refer to the specifications below for more details.

| Model | DGJ-300 | DGJ-400 | DGJ-600 | DGJ-800 |

| Power | 1.5 kW | 2.2 kW | 3 kW | 4 kW |

| Capacity | 0.5-1 t/h | 1-2 t/h | 2-3 t/h | 3-4 t/h |

| Dimension (m) | 1.29*0.88*1.35 | 1.29*0.98*1.35 | 1.29*1.08*1.35 | 1.29*1.18*1.35 |

| Weight | 350kg | 420kg | 560kg | 700kg |

Industrial Orange Juicer Machine

Who Should Buy an Industrial Orange Juicer?

Our industrial orange juicer is the perfect solution for businesses looking to process large quantities of citrus fruits quickly and efficiently. Key buyers include:

1. Large-scale Juice & Beverage Producers

Pain Point: Struggling with high-volume citrus processing while maintaining juice purity and yield.

Our Fix: Patented dual-roller press technology with juice extraction of 70%-85%. The processing capacity is up to 4 tons/h.

2. Food Processing Factories

Pain Point: Need a reliable source of fresh orange juice for sauces, dressings, jams, or desserts but struggle to maintain food safety standards?

Our Fix: Contact parts are made of 304 stainless steel, ensuring food safety. All our food processing machines, such as screw press juicer, are made of food-grade stainless steel.

3. Citrus Farms & Cooperatives

Pain Point: Unsure how to make use of surplus or second-grade fruits?

Our Fix: Our juicing units convert 3 tons of imperfect fruits/hour into premium NFC juice directly in orchards.

4. Hotels, Resorts & Fresh Juice Companies

Pain Point: High labor costs and inconsistency in the bulk fresh juice supply?

Our Fix: Large processing capacity to serve fresh juice in high volumes, ensuring consistent, high-quality production for guests or customers.

No matter your industry, our industrial orange juicer is a reliable, high-capacity solution designed to make your juice production process more efficient and profitable. Welcome to talk with us for more details!

Orange Juicer With Conveyor Belt

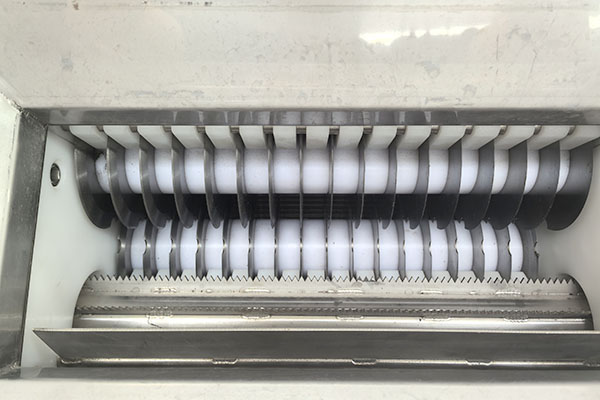

Cutting Rollers

Features of Industrial Orange Juicer

- Industrial Citrus Juicer

- Industrial Citrus Juicer

- Rollers

How Does a Roller Press Juicer Work?

Our citrus press juicer consists of multiple components, including a sturdy frame, reducer, feeding hopper, two sets of feeding rollers, two sets of pressing rollers, juice outlet, and discharge port for peels and pulp.

1. Fruit Loading - Whole fruits are loaded into the feeding hopper without peeling or sorting.

2. Cutting Process - Two sets of rotating blades cut the fruits as they move through the feeding rollers.

3. Pressing - The sliced fruits are then pushed into the space between two pressing rollers, where juice is extracted under high pressure. One of the rollers can be adjusted to regulate pressure and maximize juice output.

4. Juice & Waste Separation - Fresh juice is collected in the juice outlet, while peels and residue are discharged through the waste outlet. Below are some videos for your reference.

Videos of Industrial Orange Juicer

Trusted Worldwide - Exported to Over 30 Countries

At Furui Machinery, our roller press orange juicers have been successfully delivered to customers across the globe, including Croatia, Nicaragua, Tanzania, Algeria, Australia, Mexico, and the Philippines. We’re proud to be a trusted supplier for businesses of all sizes, and here’s why our customers choose us:

- Reliable Global Shipping - We ensure safe, on-time delivery with export-grade wooden packaging to protect your equipment during transit.

- Responsive After-Sales Support - From spare parts to video guides, we provide the resources you need to get up and running quickly.

- 3. CE-certified machines and full documentation support to help you breeze through customs clearance.

- Custom Solutions - We can provide a complete orange juice production line - including washing, automatic feeding, juicing, and packaging - tailored to your specific needs.

- Warranty & Technical Support - Enjoy a one-year warranty and lifetime technical support whenever you need assistance.

Whether you're just starting your juice business or expanding your production capacity, we’re here to support you every step of the way. Please feel free to contact us!

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat