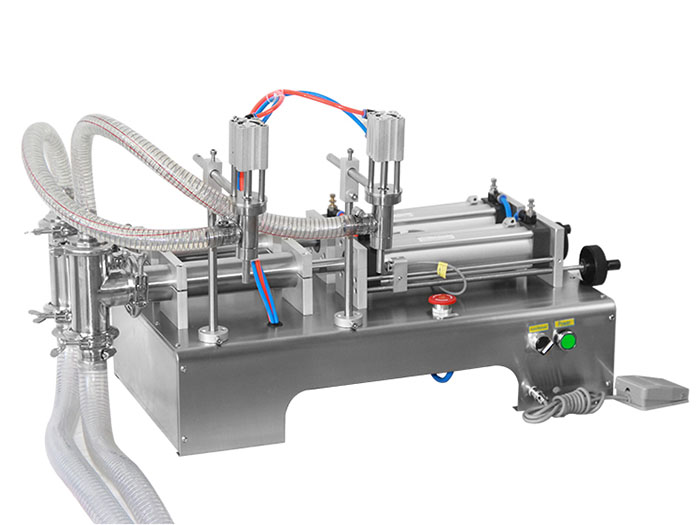

Double Head Filling Machine

Double-head filling machine is a perfect balance of efficiency, cost, and versatility. By filling two containers simultaneously, it offers twice the output of a single-head machine. Compared to 4- or 6-head machines, it is more affordable, making it an economical choice for medium-scale businesses.

- Available in semi-automatic and fully automatic configurations;

- Suitable for various products from liquids and pastes, and other viscous materials;

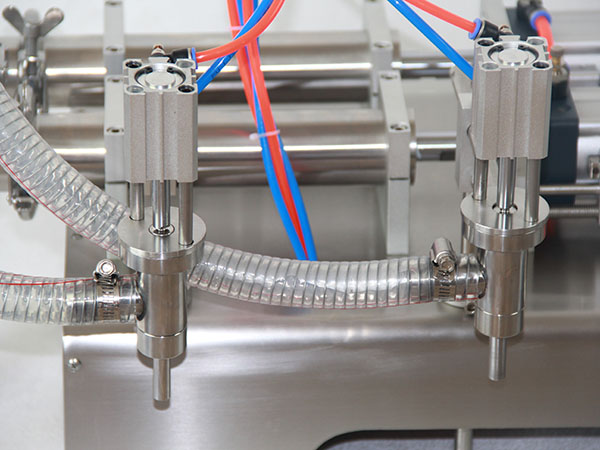

- Anti-drip design prevents liquid or pastes from dripping, reducing waste and ensuring clean, precise fills.

2-head Filling Machine

Furui Machinery offers double-head filling machines, available in both semi-automatic and automatic models. Featuring a double-head design, these machines allow for the simultaneous filling of two containers, effectively doubling production output and improving efficiency. Our double-head filling machines are equipped with versatile filling mechanisms and customized designs, making them suitable for a wide range of applications, from liquids to thick pastes. Contact us now to explore the model that best suits your specific needs!

Double Head Liquid Filling Machine

2-head Paste Filling Machine

2-head Inline Filling Machine

Applications

Furui's double-head filling machine is used across several industries, including:

- Food & Beverage: Ideal for filling sauce, paste, jam, mayonnaise, oil, juice, syrups, and more.

- Cosmetics: Perfect for lotions, creams, shampoos, gels, and other personal care products.

- Pharmaceuticals: Great for filling medicinal syrups, oil, ointments, and other medical products.

- Chemicals: Suitable for packaging paints, adhesives, cleaning agents, lubricants, and other industrial products.

| Item | Semi-automatic | Automatic (Inline) |

| Filling speed | 10-50 bottles/min | 10-100 bottles/min |

| Power | 50W | 500W |

| Voltage | 220V/110V 50/60 Hz | |

| Rate air pressure | 0.4-0.6MPa | 0.5-0.7MPa |

| Filling accuracy | ≦±1% | |

| Filling range | 5-100 ml, 10-300ml, 50-500ml, 100-1000ml, etc. | |

| Suitable containers | Bottle, can, jar, bag, sachet, pouch, etc. | |

| Product applications | For liquid, oil, paste, sauce, milk, beverage, juice, wine, paint, cream, lotion, etc. | |

Options Furui Machinery Offers

Furui Machinery offers several options for double-head filling machines, each designed to meet specific production needs.

1. Paste Filling Machine vs. Liquid Filling Machine (or Both)

Paste filling machines typically use piston fillers or gear pumps, designed with features like mixing tanks. They are ideal for high-viscosity products such as sauces, creams, butter, and lotions. While liquid filling machines operate using gravity filling, piston fillers, vacuum filling, or pump-based systems. They are suitable for thin liquids like oil, juice, wine, and beverages.

Tips: Consider the nature of your product—whether it is a liquid or paste—to select the most efficient filling system for your production needs.

2. Semi-automatic vs. Fully Automatic Filling Machine

In a semi-automatic system, an operator manually places each container under the filling nozzle, and the machine fills it. Once filled, the operator moves the container to the next step. While automated system uses a conveyor belt to transport containers, fill them, and then transfer them to subsequent stages like capping, sealing, and labeling, without manual intervention.

Tips: Consider the level of automation you need, production volume, and budget. Automated systems will increase production speed but involve higher equipment costs, whereas semi-automatic machines require a lower initial investment but slower production speeds.

By carefully assessing these factors, you can choose the most appropriate double-head filling machine that fits your production needs. If you need more details, feel free to contact us!

Features of Two-head Filling Machine

Dual-Head Design

With two heads, this machine can fill two containers simultaneously, effectively doubling the output compared to single-head machines.

Cost-Effective

More affordable than 4- or 6-head fillers, making it ideal for medium businesses.

Space-Saving Solution

Combines the output of two single-head machines in a compact design, saving valuable floor space.

High Filling Accuracy

The filling accuracy of double-head machines is highly precise, with a tolerance of ±1% (depending on the product).

Stainless Steel

The material contact parts of the filling machine are made of 304 or 316 stainless steel, ensuring high durability and corrosion resistance. This material is safe for use in food, beverage, and pharmaceutical industries, maintaining hygiene and safety standards.

Versatility

From liquid to paste, Furui’s double-head filling machine is highly versatile and can handle a variety of products. With adjustable nozzles, it accommodates various container sizes and shapes, making it perfect for a wide range of industries.

Conclusion

A double-head filling machine is an ideal solution for a wide range of businesses and industries, particularly medium-sized operations. For small-scale businesses or startups with limited production needs, a single-head machine is often the better choice. Meanwhile, for large-scale manufacturers requiring high production volumes and continuous output, multi-head filling machines (4, 6, 8, or 12 heads) are more suitable.

Furui Machinery has been trusted in packaging and filling solutions over the years. Our filling machines—whether single-head, double-head, or multi-head—are designed for precision, ease of use, and long-lasting durability. Whether you're aiming to scale up production or optimize your filling processes, Furui’s machines provide the ideal solution. Contact Furui Machinery today to discover more about our filling machines and find the perfect model tailored to your business needs.

Talk With Us Today for A Free Consultation!

Call us or contact us by WhataApp / Wechat