Dewatering Solution for Complex Waste Materials

02/12/2025

Shipping Peanut Butter Grinder Machine to Philippines

02/18/2025

Dewatering Solution for Complex Waste Materials

02/12/2025

Shipping Peanut Butter Grinder Machine to Philippines

02/18/2025Choosing between batch and continuous peanut butter production lines is critical for manufacturers balancing efficiency, cost, and scalability. As a leading peanut butter equipment supplier, Furui Machinery offers both batch and continuous processing options. This guide will help you understand the differences between batch and continuous production lines, the pros and cons, and key decision factors to help you select the ideal system for your needs.

Batch VS Continuous Peanut Butter Processing

Batch Production Process

In a batch processing system, peanuts undergo roasting, cooling, peeling, grinding, and mixing in distinct batches. Each step must be completed before starting the next batch, often leading to waiting periods between stages.

- Best for: Small to medium-scale production (100-500 kg/h).

- Operation: Each batch operates in separate stages, and production pauses between batches for processing and cleaning.

Continuous Production Process

a continuous processing system automates each step in the peanut butter production process. Peanuts move seamlessly through stages - roasting, cooling, grinding, and blending - without interruptions. The process runs continuously, maximizing efficiency with minimal downtime.

- Best for: Built for large-scale, high-volume manufacturing with minimal downtime, generally 500-3,000 kg/h.

- Operation: A continuous, uninterrupted flow of materials through the processing stages.

Drum Nut Roaster

Belt Nut Roaster

Key Differences - Equipment & Costs

1. Roasting and Cooling Systems

Batch Process: Drum Roaster with Cooling Belt

-

Drum-Type Roaster: Uses a drum-type roaster, where peanuts are roasted in rotating drums for even heat distribution.

- Cooling Belt: Roasted peanuts are cooled with a cooling belt before entering the peeling stage. This method allows batch-by-batch roasting and cooling.

Continuous Process: All-in-one Belt Roasting and Cooling System

- Belt-Type Roaster: An automated drying and roasting machine that uses a mesh belt conveyor and hot air circulation to dry peanuts efficiently.

- Integrated Cooling: Cooling systems are built into the conveyor line, enabling a seamless transition to grinding.

2. Material Transfer

- Batch Process: Peanuts are manually or semi-automatically transferred between stages, which can slow production. Lifting machines or conveyor belts can be used to improve efficiency.

- Continuous Process: Multiple elevators and conveyors automate material transfer, ensuring a smooth and efficient operation.

3. Costs

-

Batch Process: Lower initial investment but higher long-term labor costs.

-

Continuous: Higher upfront costs offset by lower operational expenses and labor savings.

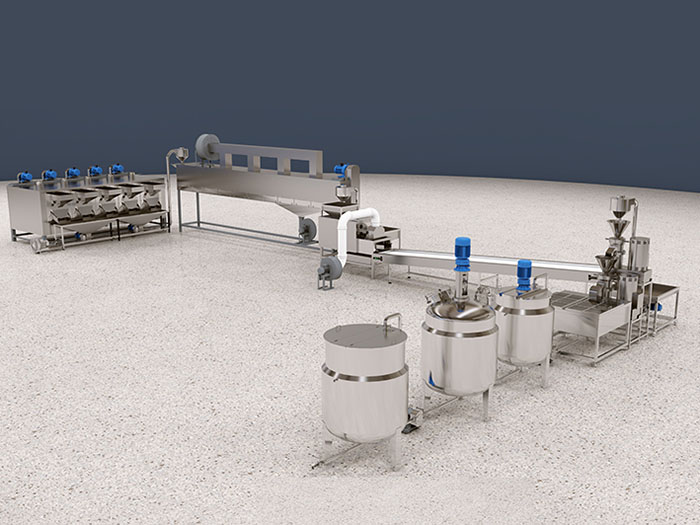

Batch Peanut Butter Production

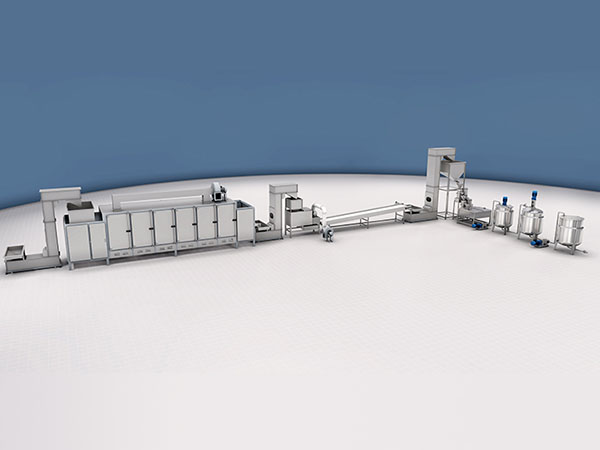

Continuous Peanut Butter Production

Advantages and Disadvantages

Batch Production: Best for Small to Medium-Scale Operations

Pros:

- Flexibility: Easily adjust recipes between batches (e.g., chunky vs. smooth).

- Lower Initial Cost: Smaller equipment is ideal for startups or small and medium-sized businesses.

- Less Risk of Contamination – Since cleaning can be done between batches, reducing cross-contamination.

- Simpler Maintenance – Downtime for cleaning and repairs is easier to manage.

Cons:

- Lower Output: Typically limited to 100-500 kg/hour, depending on equipment.

- Inconsistency: Slight variations between batches.

- Higher Labor Costs: Requires manual monitoring and handling.

- Lower Efficiency – Frequent stopping and starting will result in longer production time.

Continuous Production: Best for Large-Scale, High-Volume Operations

Pros:

- High Output: Produces 500-3,000+ kg/hour for mass-market distribution.

- Consistent Quality – Uniform processing reduces variations in texture and taste.

- Lower Labor Costs – More automation reduces manual intervention.

- Better Cost Efficiency in Large-Scale Production – Reduced waste and energy consumption per unit.

- Less Downtime – No need to stop for batch changes.

Cons:

- High Upfront Cost: More advanced equipment and automation are required.

- Complex Maintenance – Repairs and cleaning must be carefully planned to avoid major disruptions.

- Less Flexibility – Not ideal for small batches or frequent recipe changes.

500-kg Peanut Butter Production Line to Algeria

How to Choose the Right Production Line?

Choose a Batch Production Line If:

- Your operation is small or medium-scale (less than 500 kg/h).

- Flexibility in recipes and flavors is important to your business.

You have a limited budget or space for equipment.

Choose a Continuous Production Line If:

- You need large-scale, high-speed production (more than 1,000 kg/h).

- Consistent quality and cost efficiency are crucial, especially if labor costs are high.

- You have the budget and space for advanced machinery.

Furui Machinery: Your Trusted Partner

As a leading supplier of peanut processing technology, Furui Machinery delivers customized solutions for both batch and continuous systems. Our equipment ensures precision, reliability, and scalability, covering every stage from roasting to packaging.

Need expert advice on the best processing solution for your peanut butter business? Contact Furui Machinery today to explore our full range of peanut butter processing equipment and let us help you choose the perfect system for your needs.